nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 2:31 PM

(permalink)

The update will be replacing that radiator fin assembly, with a waterblock to cool the hot sides of the tec.

Basically, a tec sandwich.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 2:38 PM

(permalink)

LOL disregard that PM i sent you, you just answered my question.

What are the spec's of the TEC's you are using?

Vmax, Imax, DT, Qmax...etc

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 2:42 PM

(permalink)

Ask this dude: thePoison If your looking for the TEC Mac-daddy, talk to this dude: lehpron

post edited by nateman_doo - Friday, February 10, 2012 2:46 PM

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 2:48 PM

(permalink)

Do you use rubber o-rings/gaskets for the majority of your water blocks?

Have you tried brazing the copper together with silfos or silver to get an air right, water tight seal?

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 2:56 PM

(permalink)

My personal preference is permatex, but most people want O-rings.

I wanted to braze it this block, but he wanted an O-ring. I aim to please.

If you would like one I would be more then happy to braze it for you.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 3:26 PM

(permalink)

I absolutely will be getting one....but I dont quite know what I want yet.

I like the idea of sandwiching TEC's, but I like going big.

5 water blocks, 4 are 42mm x 242mm x 12mm, the last one is a 88mm x 242mm x 16mm....roughly. I having added in the room needed for threading.

Thats just off the top of my head.

What my plan is having the larger waterblock, in the middle and will act as the hot side for all the TEC's. My plan is to have 24 TEC's running along both sides of the larger water block, in 4 rows of 6 TEC's. The 4 other water blocks would sit on the cold side of the TEC's mounted to the larger water block.

this is of course just a thought but I will be looking for something similar to this and along these lines. Feel free to make any suggestions to what you see as an improvement.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Friday, February 10, 2012 3:52 PM

(permalink)

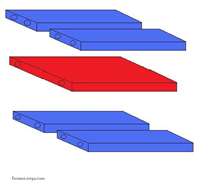

a picture is worth a thousand words ;) I am sure you heard that one before? Here is what I see you saying:  Now my simplification: why not just make 3? Keep the large center block for all the hot sides, and 2 for the cold sides?

Attached Image(s)

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Saturday, February 11, 2012 2:43 PM

(permalink)

Yeah that's exactly what I'm talking about. I would have drawn you a picture but I severely lack artistic skills.

The reason I wanted 2 blocks on the top and bottom was because of the number of TEC's used....but I think you are right. One larger one on the top and bottom would be better and yield the same results.

|

nikkocortez

CLASSIFIED Member

- Total Posts : 2625

- Reward points : 0

- Joined: 2/1/2010

- Status: offline

- Ribbons : 14

Re:6x6x1 TEC Block (CNC action)

Saturday, February 11, 2012 3:42 PM

(permalink)

The great thing about technical drawings is you don't need artistic skills.  What a lot of people mistake with artistic skill is that its the only ability to graphically present an idea, while, yes, that is the major part of art but you are trying to explain a piece of hardware, not necessarily explain a type of emotion. Its a lot easier to explain hardware... although you luckily are a part of a group here who gets very emotional at the sight of hardware  so give it a shot with a ruler and a pencil. You will be surprised with how good you are!  Once you learn a CAD type of program or Google Sketchup (which is a lot easier to learn) you can let your creative engineer inside you go all out.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Saturday, February 11, 2012 4:28 PM

(permalink)

Thank you for the tip nikk. I'm going to look that up and start practicing. Are they freeware? If not what is the easier CAD type software to learn from I should buy?

|

nikkocortez

CLASSIFIED Member

- Total Posts : 2625

- Reward points : 0

- Joined: 2/1/2010

- Status: offline

- Ribbons : 14

Re:6x6x1 TEC Block (CNC action)

Saturday, February 11, 2012 4:47 PM

(permalink)

Google Sketchup has a freeware version that most people use!  Its pretty easy to use and there are lots tutorials for it as well. A lot of people here on the forums use it including GoneCrusing who builds some sweet Computer cases. I use AutoCAD for work so I prefer that personally but that's just because I am more familiar with how to use it. Google Sketchup!  Whats great is there is a community with Sketchup and you can basically Google up built models like some motherboards and fans to add into your designs so you dont have to build completely out of scratch. Most are built to scale as well. Just keep your eye out for dimensions for what you want to build and use that to go off of when designing. Most places have dimensions of parts available and you can always Google technical drawings for basic parts to go off of.

post edited by nikkocortez - Saturday, February 11, 2012 4:51 PM

|

lehpron

Regular Guy

- Total Posts : 8858

- Reward points : 0

- Joined: 5/18/2006

- Status: offline

- Ribbons : 191

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 0:45 PM

(permalink)

nateman_doo

The update will be replacing that radiator fin assembly, with a waterblock to cool the hot sides of the tec.

Basically, a tec sandwich. What, kinda like this?   Except you have two sets of tecs and a CPU pass through loop in the middle, from what I see.

|

nikkocortez

CLASSIFIED Member

- Total Posts : 2625

- Reward points : 0

- Joined: 2/1/2010

- Status: offline

- Ribbons : 14

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 1:58 AM

(permalink)

BTW is there anything known as being a good controller for these TECs? Or are they just running all the time? I would love to integrate TECs into a project of mine but it seems like a controller would have to be built from scratch unless you scavenged one from a Cool-it TEC unit. Any one make anything?

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 2:38 AM

(permalink)

The easiest way is via a potentiometer. All a TEC uses is voltage so if you control that you can control its strength. If you are looking for an auto-adjusting voltage regulator based off coolant temps you are going to have to design one yourself or have one desigened for you. Potentiometer is the easiest was IMO.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 2:40 AM

(permalink)

The one that comes from Coolit Systems isn't the best. It's ok for what it does but you will be better off making your own.

|

Halfdead14

SSC Member

- Total Posts : 973

- Reward points : 0

- Joined: 7/18/2009

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 6:13 AM

(permalink)

I know that someone from OCN forums has a custom made controller for TEC systems.

|

thePoison

SSC Member

- Total Posts : 951

- Reward points : 0

- Joined: 6/2/2008

- Location: Indiana

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 7:44 AM

(permalink)

potentiometer would fry, the best is a SSR with full blown PWM, i have a schematic around here that I used to make mine, it works quite well allowing a 12v fan header to control the power output for my TEC's. Also to the person inquiring about the 24 TEC's, that setup in materials would probably cost you almost as much as your system.

Case: Lian-Li PC-V2120 PSU: Seasonic X-1250 MB: ASUS Maximus IV CPU: Intel Core i7 2600k @ 4.6 GHz with Switech Apogee XT R2 RAM: 8 GB Kingston (2x4GB) 1600 Mhz GPU: Geforce 780 @ 1.15 GHz with Aquatuning water blocks. OS: Win 8 x64 Pro Driver: 326.80 Voltages: 1.33 CPU, 1.65v RAM

Storage: 2 Samsung 840 Pros in Stripe + 1 TB WD Black Caviar + 2 TB WD Black Caviar

|

chillernr1

SSC Member

- Total Posts : 519

- Reward points : 0

- Joined: 1/17/2007

- Status: offline

- Ribbons : 6

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 9:46 AM

(permalink)

nikkocortez

Like this i'm planning to make also a Extreme Coolit Boreas chiller, like i'm using now in my rig. But one that cools better and more. first drawings are ready, just have the make the first copper plates of the grill, just looking for somebody to make the copper blocks for me.

|

nikkocortez

CLASSIFIED Member

- Total Posts : 2625

- Reward points : 0

- Joined: 2/1/2010

- Status: offline

- Ribbons : 14

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 12:31 AM

(permalink)

@ Chillern- Nateman_doo is the man for copper blocks!  Yeh I liked the idea of the Boreas Chiller but it seems dual loop cooling is the way to go. In all honesty your rig is what got me intrigued with TECs.  Yeah to me it would be controlling the TECs with a good PWM controller unit. I'm sure if I had the schematics I could throw one together. I would just prefer it to be better controlled based on what the computer needs that way it could cut down on being extremely sub-ambient all the time and less risk for condensation.

post edited by nikkocortez - Sunday, February 12, 2012 12:36 AM

|

chillernr1

SSC Member

- Total Posts : 519

- Reward points : 0

- Joined: 1/17/2007

- Status: offline

- Ribbons : 6

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 1:34 PM

(permalink)

use an arctic tec controller or a coolit controller for controlling you're tec's

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 1:42 PM

(permalink)

I do realize how much TEC's and that set up in general would cost as I have spent thousands already on my current cooling system. What I'm looking for is a more permanent and effective way of cooling and further reducing my temps. I am currently running 3 Boreas chillers for two computers, 36 TEC's in total.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 1:45 PM

(permalink)

Also you only fry TEC's if you over voltage them. If you select the right size potentiometer you will have no worries as the voltage will never exceed the TEC's Vmax.

|

chillernr1

SSC Member

- Total Posts : 519

- Reward points : 0

- Joined: 1/17/2007

- Status: offline

- Ribbons : 6

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 3:02 PM

(permalink)

JaskarnSidhu

I do realize how much TEC's and that set up in general would cost as I have spent thousands already on my current cooling system. What I'm looking for is a more permanent and effective way of cooling and further reducing my temps. I am currently running 3 Boreas chillers for two computers, 36 TEC's in total.

i have 24 TEC's in total in my daily rig.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 11:34 PM

(permalink)

Here is my input on temp control.

If your looking for super cold, go full throttle on the voltage and give the tec's what the want as far as voltage. Then insulate your board. (see the get it colder thread & sift through the early 300 pages of info on insulation)

The other thing you can do is install a thermal type of relay sort of like a thermostat. It will control your temps to the dew point. Your tec's will go full throttle until the block has cooled to a certain temp, and it will keep cycling them. Thats what we do with our chillers.

Having never officially working with tec's. I have no idea what the implications of cycling them frequently over long term would be, but why not experiment with one? They don't cost much.

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Sunday, February 12, 2012 11:58 PM

(permalink)

chillernr1

JaskarnSidhu

I do realize how much TEC's and that set up in general would cost as I have spent thousands already on my current cooling system. What I'm looking for is a more permanent and effective way of cooling and further reducing my temps. I am currently running 3 Boreas chillers for two computers, 36 TEC's in total.

i have 24 TEC's in total in my daily rig.

Do you have you TEC's undervoltaged or all of them at full power? What are your temps like?

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Monday, February 13, 2012 0:15 PM

(permalink)

TEC's are slow to cool down and by slow I mean can take up to a minute to reach thier max efficiency. So if you are planning on have a temperature controller it will always be delayed by at least 30 seconds if not more.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 1/16/2008

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:6x6x1 TEC Block (CNC action)

Thursday, February 16, 2012 7:11 PM

(permalink)

So what do you plan to have done?

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Thursday, February 16, 2012 7:26 PM

(permalink)

I'm away from my home computer so I don't have my notes and plans on me but I'm thinking about having a TEC cooled water chiller that feeds into a TEC cooled water reservoir. The plan is to have the TEC's connected in series and parallel and have them on a powersupply with adjustable output voltage.

|

thePoison

SSC Member

- Total Posts : 951

- Reward points : 0

- Joined: 6/2/2008

- Location: Indiana

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Thursday, February 16, 2012 7:27 PM

(permalink)

I've seen Arqtik cooling controller melt on the power connector going to the TEC's, i have pictures of it if you don't believe me (not my set up but their premade kit). As far as how I power my TECs, and you can probably ask leopron this and he should confirm it, usually best to undervolt your TEC's and have a very large array of them for efficiency and cooling. Also air cooling is possibly the least effective way to cool a TEC. Their surface area just too darn hot. If I remember, those TEC's on the boreas chiller run only as 12 watts each. In all fairness with the one's i've been using (4 between 8) for best results;they can pull upwards of 1000 watts on 12v. I usually run my tec's at their sweet spot of 7-9 v. With air cooling them I was getting no where near what i desired, after getting a hold of some old enzotech gpu universal water blocks and testing how they perform with their hot side cooled with liquid, the temperatures hit below freezing relatively quick.

post edited by thePoison - Thursday, February 16, 2012 7:34 PM

Case: Lian-Li PC-V2120 PSU: Seasonic X-1250 MB: ASUS Maximus IV CPU: Intel Core i7 2600k @ 4.6 GHz with Switech Apogee XT R2 RAM: 8 GB Kingston (2x4GB) 1600 Mhz GPU: Geforce 780 @ 1.15 GHz with Aquatuning water blocks. OS: Win 8 x64 Pro Driver: 326.80 Voltages: 1.33 CPU, 1.65v RAM

Storage: 2 Samsung 840 Pros in Stripe + 1 TB WD Black Caviar + 2 TB WD Black Caviar

|

JaskarnSidhu

SSC Member

- Total Posts : 837

- Reward points : 0

- Joined: 6/2/2011

- Location: Edmonton, Alberta, Canada

- Status: offline

- Ribbons : 2

Re:6x6x1 TEC Block (CNC action)

Thursday, February 16, 2012 7:37 PM

(permalink)

thePoison

I've seen Arqtik cooling controller melt on the power connector going to the TEC's, i have pictures of it if you don't believe me (not my set up but their premade kit). As far as how I power my TECs, and you can probably ask leopron this and he should confirm it, usually best to undervolt your TEC's and have a very large array of them for efficiency and cooling. Also air cooling is possibly the least effective way to cool a TEC. Their surface area just too darn hot. If I remember, those TEC's on the boreas chiller run only as 12 watts each. In all fairness with the one's i've been using (4 between 8) for best results;they can upwards of 1000 watts on 12v. I usually run my tec's at their sweet spot of 7-9 v. With air cooling them I was getting no where near what i desired after getting a hold of some old enzotech gpu universal water blocks and testing how they perform with their hot side cooled with liquid, the temperatures hit below freezing relatively quick.

I'm sorry I misunderstood your original post and thought you ment the TEC's themselves would get fried. You are absolutely correct as higher currents will infact melt the plastic around the TEC connectors. Easiest way to prevent that (space permitting) is add a fan blowing across the connector or move the connector on the path of a fans air flow.

|