Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 09:12:52

(permalink)

The orientation is great The dragon looks even better now that I'm seeing the mock up ;) Oh and what about putting Nate's mark up with the inlet and outlet? Using them as part of his sign?

post edited by Forgotton - 2011/05/10 09:20:29

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 16:28:42

(permalink)

Nate still needs a logo or something.

That dragon is pimpin. What type of bits so you use?

|

RBIEZE

CLASSIFIED Member

- Total Posts : 3072

- Reward points : 0

- Joined: 2007/02/21 00:13:33

- Location: Northern Illinois...lurking in the Corn

- Status: offline

- Ribbons : 12

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 16:39:45

(permalink)

Yo Nate,blocks looking good !!!  Looks like Ill be doing this for my X58 4way classy board. First 90f degree day of the year and the mosfet and chipset coolers are so hot the almost burn my hands.

post edited by RBIEZE - 2011/05/10 16:46:54

They say opposites attract. I hope you meet someone who is good-looking, intelligent, and cultured. http://www.youtube.com/watch?v=W2WsPN-rr9o Evga X58 4Way sli,W'Cooled i7 950 @3.8, Mushkin redline mem @6-7-6-18 1600Mhz, 2-Evga GTX770 Sli, Evga Gtx460 Physx, Corsair Neutron 120GB SSD,Samsung 240SSD, W.D Black 640GB /Corsair TX950 Psu, Hanns-G 28" Lcd, Logitech G540 5.1 Surround My Affiliate Code: EECLVEDV7Z

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 16:46:09

(permalink)

thanks! I finished a black Acetal-copolymer top. Pics to come soon.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 17:13:26

(permalink)

on the dragon I will need to use a .005 diamond spinable to get the detail. basically a sharp pointed one  I think you can get a collet adaptor for engraving bits. not sure exactly what chuck/collet your spindle has. I would run this with a specialized engraving head(low torque with spring loaded pressure plate). Its really not a mill or router, just a really big spring loaded dremel sorta. Designed specifically for engraving.(thats all that head does) and yes, Nate still needs a logo.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 17:20:08

(permalink)

I was thinking you would need something spring loaded to accommodate imperfectly flat surfaces. I can only get around 3K rpm, but the end mill can remove copious amounts of material.

I was thinking if I "engrave/mill" I can sandblast the top, then sand it down so the logo will stick out as a soft matte finish against a shiny brushed finish.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 17:34:51

(permalink)

yah, thats the look I was thinking on mine. on the dragon though if the sandblasting is really deep the profile will need to be milled flat so that the engraving will not lose its detail in the sandblast. which will then make the dragon stand out nicely I think. depends how deep the sandblasting is. keep in mind you can just use regular masking tape to mask areas that you do not want to blast. actually just re-read your post. I'm after the opposite I guess, but yah a raised logo is cool

post edited by Gratuitous - 2011/05/10 17:38:31

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 17:49:27

(permalink)

a raised logo would take forreeevvveerr! removing all the material thats not in that dragon? wow, i would be curious to see how many tens of thousands of lines of code that would be. it was over 3K for just the classy logo! Edit: thats a job for CAM software, and Tool changing capabilities.

post edited by nateman_doo - 2011/05/10 17:56:18

|

RBIEZE

CLASSIFIED Member

- Total Posts : 3072

- Reward points : 0

- Joined: 2007/02/21 00:13:33

- Location: Northern Illinois...lurking in the Corn

- Status: offline

- Ribbons : 12

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 18:01:26

(permalink)

If you face the workpiece, then immediately engrave the design without disturbing the workpiece setup , no spring loaded mill is necessary or desired.

I did quite a bit of non EDM die blanking in tool steel many years ago, we did it on basic Bridgeport ram and turret mills with a spindle speeder.

steady hands, slow feeds, and finesse were required , or you would break the endmill.

The recomended setup would be a 30,000+ Rpm spindle or conversely,at 3000rpms, VERY very slow feeds.

They say opposites attract. I hope you meet someone who is good-looking, intelligent, and cultured. http://www.youtube.com/watch?v=W2WsPN-rr9o Evga X58 4Way sli,W'Cooled i7 950 @3.8, Mushkin redline mem @6-7-6-18 1600Mhz, 2-Evga GTX770 Sli, Evga Gtx460 Physx, Corsair Neutron 120GB SSD,Samsung 240SSD, W.D Black 640GB /Corsair TX950 Psu, Hanns-G 28" Lcd, Logitech G540 5.1 Surround My Affiliate Code: EECLVEDV7Z

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 18:07:56

(permalink)

That would also how I would do it. Not with a face mill, but with a 1/2" end mill running with overlap. I already have a jig which gets the part right back into the same spot every time, and the screws are countersunk, so facing 0.01" won't be a problem. It could EAT through material at that depth with the quickness. practically at G00 speeds.

|

RBIEZE

CLASSIFIED Member

- Total Posts : 3072

- Reward points : 0

- Joined: 2007/02/21 00:13:33

- Location: Northern Illinois...lurking in the Corn

- Status: offline

- Ribbons : 12

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 18:17:54

(permalink)

I never asked you what you G00 rapid was at Nate / Ive got mine capped at 25ipm now on the X and Y and 15 on the Z axis, but had it at 75ipm when I first did the cnc conversion . After my first crash/collision ($$$) I dropped it down for sanity sake,,,(me scared of breaking mill again...)

They say opposites attract. I hope you meet someone who is good-looking, intelligent, and cultured. http://www.youtube.com/watch?v=W2WsPN-rr9o Evga X58 4Way sli,W'Cooled i7 950 @3.8, Mushkin redline mem @6-7-6-18 1600Mhz, 2-Evga GTX770 Sli, Evga Gtx460 Physx, Corsair Neutron 120GB SSD,Samsung 240SSD, W.D Black 640GB /Corsair TX950 Psu, Hanns-G 28" Lcd, Logitech G540 5.1 Surround My Affiliate Code: EECLVEDV7Z

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 18:21:28

(permalink)

at least 30 ipm I think are my rapids, and I have that bell curve to about the middle of the chart as far as speed goes. I really am not in any rush for the rapid commands.

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 20:13:25

(permalink)

While a raised Logo might be nice I'm more worried about the detail and making sure it looks good I plan on using lighting to accent the dragon. And so the carved in vision of the dragon I believe will be the best move the light should play with the indentations. I thank you both for making this happen for me and I know it will look marvelous when it all comes together I'm also seeing if I can get CaseLabs to do some things similarity things to make my build monumental. I'll see if i can get you some help for a personalized logo Nate, And I'll be sure to have your logo lighted as well. ;)

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 20:28:19

(permalink)

When it comes to lighting, I think nothing has better sex appeal then Plexi. If LED's are embedded into the plexi and it lights the edges up, nothing compares to it. Anyhow, as promised, pics of the acetal co-polymer:  Its not polished at ALL, this is just how it looks after a rough cut. It looks like marble when its all polished and clear coated. It really is a thing of beauty.

Attached Image(s)

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 20:36:37

(permalink)

Nate your thoughts on the Plexiglas have given me an idea. What would you think of adding Plexiglas on top of the Copper full build a second top. and we take your Raised Image idea only do it on the bottom of the Plexiglas so it seams like the dragon is contained inside the Plexiglas or the copper below? Basically fit the raised and lowered images into each-other with the Plexiglas atop the copper roof of my Block?

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 20:57:51

(permalink)

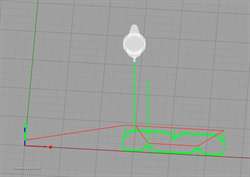

Everything has to fit in a 1/2" thickness. It sounds interesting, but it would take quite a bit of coding. Speaking of coding, the O-ring for the V-reg block is done:

Attached Image(s)

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/10 21:02:01

(permalink)

I understand it may not be easy but i am willing to fund the attempt if you are willing to put in the time. The block is your baby So I am willing to wait till your machine can do the fine work on the Copper If you feel you will be unable to do this then I'll see if Gratuitous will be willing to give it a shot ;) The ball is in your court! :)

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/11 03:59:58

(permalink)

If your not in any rush, it would take a while to build another machine.

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/11 04:25:18

(permalink)

nateman_doo

If your not in any rush, it would take a while to build another machine.

The Idea of having it soon while appealing is no where near as appealing as having it look even more awesome within my build ;) I am working on getting the TX-10 case which is still being developed and will take me minimum till next month to have the full amount to pay for the case. And I haven't even gotten to saving for the processors for my board yet. So Time I have Patience I have, Money builds up slowly and parts.. Well they can be even slower for me. LOL so yes Nate I am Quite willing to wait ;)

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/11 14:03:14

(permalink)

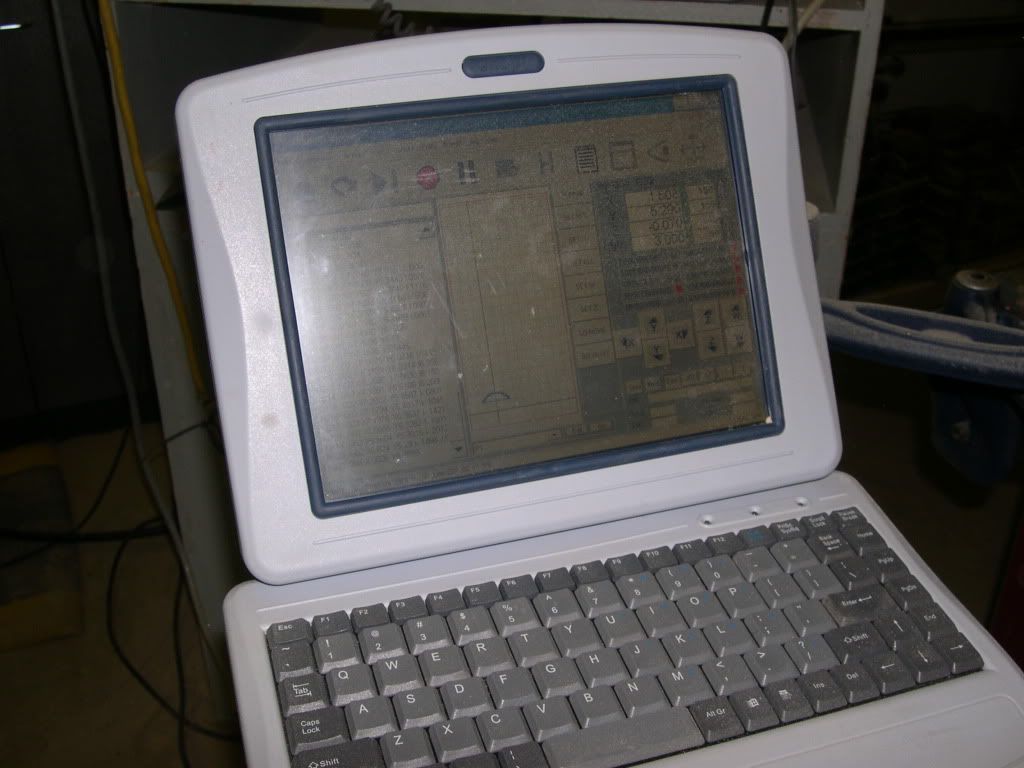

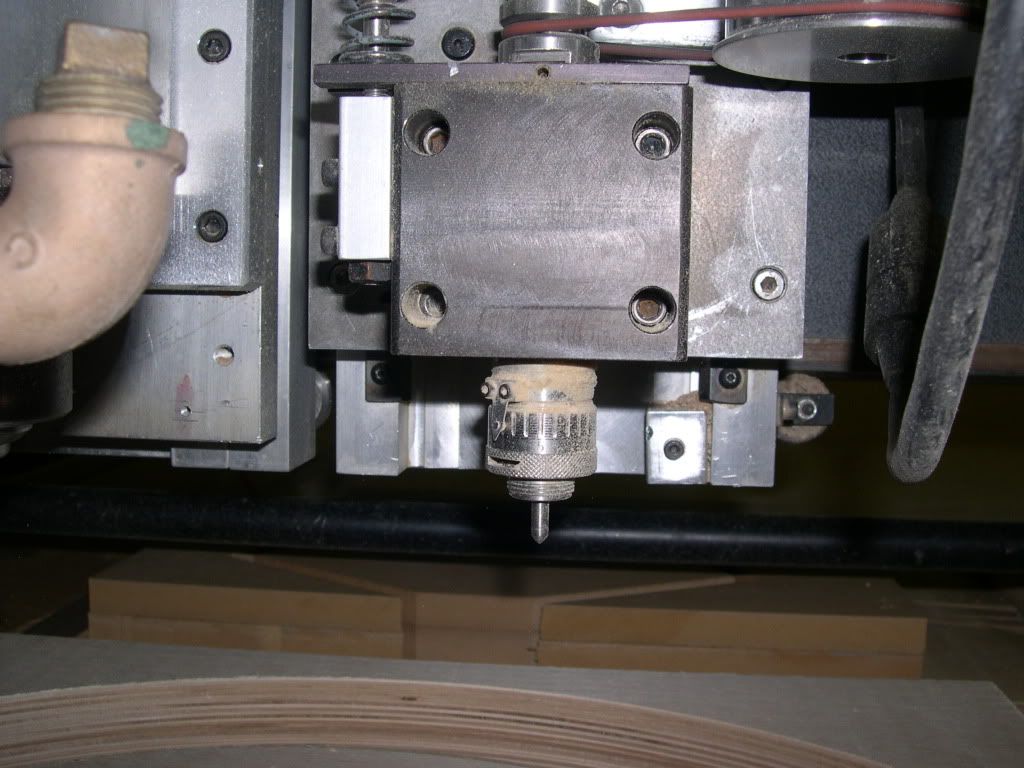

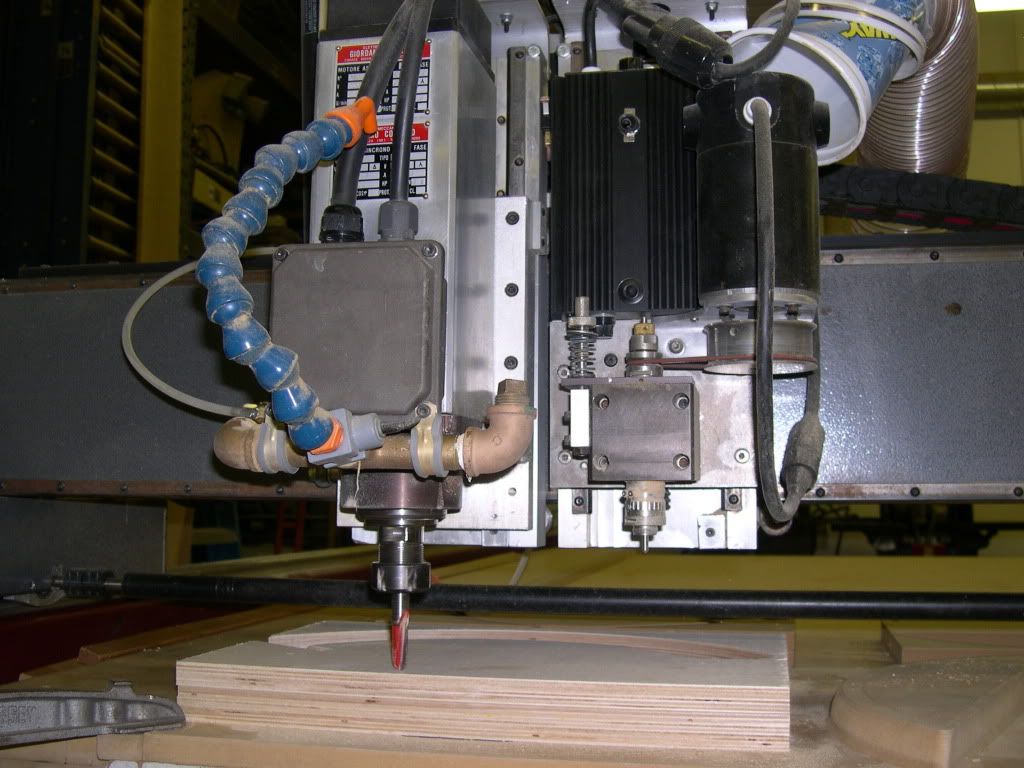

interesting ideas  I can code anything, only making 2 reliefs fit together and look perfect will be a challenge. at least from that low res jpeg. do me a favour and see if you can find a higher res version of that dragon. If not I can clean it up a bit by hand. I did a search for other images and tbh, that one is the nicest for our application that I was able to find. things that make a jpg good for extracting vectors: greyscale high contrast well defined lines high resolution etc. obviously the best form of graphic for a cnc guy to work with is one that uses vectors. but that is rare to find unless someone has made the logo/graphic for you. I will post some pics tonight of my engraving head. It sits on the W access on my 7x14 router table next to the Z spindle. the spring loading of the engraving bits is crucial when I do engraving on bigger sheets of material, because the material hieght can vary a lot. (.005+-) and that can make the diference of a muddy looking engraving and a clean sharp one when dealing with very detailed vectors. It is also used to set a down pressure which causes a defined line when set properly. think deep scratches as opposed to actual milling. now when I use an endmill to engrave on the spindle its a whole diferent process, similar to how nate does it, but my spindle is 24k rpm and 15 hp I have rapid of 500ipm and run most of my work in wood and plastics at 50-200ipm. I can slow everything way down but it wont spin at less than 1000 rpm so I cant do any threading on it. also it is no mill, it just doesnt have the beef behind it like a traditional mill does even though I can do a lot of the same type of work. I also have no liquid cooling avalable with this setup. I do use forced air to cool the bit but liquid would not be a good idea with this kind of table. I also have a 150w laser on a 4.2'x24' table for cutting and engraving and I have 1/2 of a bridgeport nee mill sitting in the corner waiting for us to find the time to retrofit with a new controller. certain materials just dont play nice with the laser, I havnt tryed copper yet but I might try a sample to see what that looks like.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 05:33:41

(permalink)

UPDATE

Milling out the small extrusions in the bottom plates to allow clearances for the large components.

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 05:54:13

(permalink)

Nice to hear you are Progressing nate!

I had a thought, yes i know dangerous and my head may over heat ;P However I'll list it here anyways. hehehe, I will be the first to admit I have basically zero knowledge of how the machines you 2 are using to do the engraving and creation of custom pieces. So having admited that please go easy on me if this is just completely idiotic or so far off how its done to be laughable.

Would just Inverting the programing for the engraving of the dragon work to make your mill do a raised image of the dragon? Basically tell the machine to cut everywhere BUT where the lines are for the image, And changing the depth to dig to in the engraving to a depth to dig the rest out?

I do find what you are doing quite interesting and wouldn't mind some day perhaps building my own. So my question is me trying to understand the way the coding works in addition to seeing if i can even some day get to the point where I may be able to do what you are doing for me.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 06:05:10

(permalink)

A mill is designed to remove material. You start with a chunk of metal, and the endmill removes the metal that is there. Either it removes the area around your design, or remove the material that is your design.

As far as coding, Gratioutious is FAR better then I am, and has software to aid. I am doing everything by hand, plotting grid coordinates and manually entering each line of code.

Youtube milling, (perhaps 5 axis CNC milling). Every time that machine moves in any 1 movement, that is a line of code, and while its moving along a path, its called a tool path. I haven't really had time to sit down and learn a CAM (Computer aided manufacturing which programs all those tool paths), but I can do overall larger scale plotting, like the blocks you see in the pics.

The engraver basically scratches the surface to various degrees. Both are similar, and are like drill presses that they basically spin a tool. Sounds like his is pretty beefy. I have saved some videos of my mill in operation, but I just haven't loaded them up on youtube yet.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 11:27:31

(permalink)

some pics of my setup:      so on the right you can see the engraving head and on the left the spindle. it is all controlled via the touchscreen. so to answer your question Forgotten: with a small detailed engraving like the dragon, to mill everything except the lines for the dragon is not feasable, but what can be done is mill everything except a sortof profile of the surrounding object and then engrave the fine lines on the raised surface. think of a rased outside shape of .01 or so then the fine lines 'scratched' in at a depth and width of .005". so what i'm trying to say is, that when a line that is .005 thick is .01 or less away from another .005 line it is very hard on this sort of equipment to mill out the .005 between the lines to actually cause it to look raised. now if the lines ar .0625(1/16") thick with at least .0625 space between them , it would be much easier to mill between the lines to remove everything except the line. ... does that make sense? now the other consideration is machine time. guys like me who use our machines to make a living, try to get a certain amount an hour that the machine is running. (sucks a lot of energy, bit wear, shop overhead, etc.) just engraving without milling around the surrounding area takes a lot less time than milling out the entire piece except for the logo. so machine time does play a large role in how a job is designed. as far as labor goes, usually on a long job, we can walk away from it and come back to it once it is finished, so we dont have to actually be in front of it the whole time. so if you look at the pictures above you will see a job that I am milling for a customer. it is 1.75" think birch. the curved side is milled down .01" per pass. put into perspective, it takes 30 min for one of those to be shaped. and that is 5k lines of code because it is not a true arc. hope this helps you get an idea how it works.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

zurginator

SSC Member

- Total Posts : 643

- Reward points : 0

- Joined: 2009/03/31 13:29:43

- Status: offline

- Ribbons : 3

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 12:04:15

(permalink)

Made you a logo Nate. ;)

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 12:55:52

(permalink)

if nate likes it, can you pm me the original file? so i can code it for him? a vector file such as from AI or coreldraw or something is obviously much better for me than a jpg. but high res jpg will work if you did it in paint or some other bmp.

looks cool

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 14:29:07

(permalink)

umm... thats MR T. I need my own logo ;)

I have a few ideas, but I am working on that.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/12 14:35:32

(permalink)

dont bother sending the file to me then:) Nate send me what you had in mind if you want.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/16 07:24:41

(permalink)

working on some logos, but just tossing ideas around at this point.

|

Forgotton

iCX Member

- Total Posts : 456

- Reward points : 0

- Joined: 2011/04/13 03:14:25

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/16 07:42:36

(permalink)

for the logo how about a fancy version of this:

"Doo It The NateMan Way!"

use an "O" in the inlet and the "A" as the outlet?

|