ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 2008/04/10 23:48:15

- Location: traveler

- Status: offline

- Ribbons : 271

Re:100% Copper SR2 full coverage waterblock!

2011/04/26 22:02:43

(permalink)

Nice! A plexiglass top would be awesome.

I am a fan of plexi tops myself since it allows you to see any trouble that might be brewing.

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

texinga

CLASSIFIED ULTRA Member

- Total Posts : 5066

- Reward points : 0

- Joined: 2010/07/03 14:30:32

- Status: offline

- Ribbons : 22

Re:100% Copper SR2 full coverage waterblock!

2011/04/27 08:56:38

(permalink)

Nate, you gotta lay that Plexi-top over your waterblocks and snap a pic so we can see the full effect!

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/27 09:04:17

(permalink)

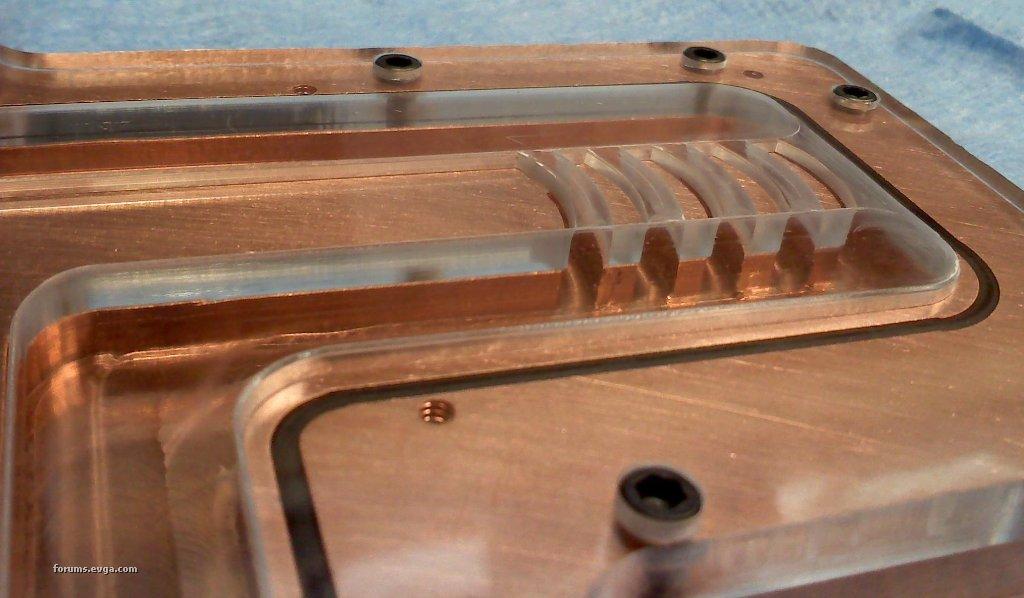

A look at the machining of the Acrylic:  The plastic coating didn't hold up to well to the machining and the flood coolant. Here its washed off a bit:   Here its polished a little bit with some polishing compound:  Its sitting on an old shop towel and my laptop. You can see the logo and details of the shop towel clearly. A view from the underside of the top piece.  Not bad for my first crack at it

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/27 09:14:13

(permalink)

texinga

Nate, you gotta lay that Plexi-top over your waterblocks and snap a pic so we can see the full effect!

I was still cutting top sections of blocks. Bottom sections are up next. I am making a jig since my tool plate is being eaten alive by all the milling & drilling.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 00:48:49

(permalink)

looks great man  A trick for the outside edges on plexi is flame polishing. puts that glass finish on real quick. only you have to practice a bit to get the ballance between glass smooth and rounding the edges. Keep up the good work.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 08:04:48

(permalink)

I ran into a slight problem when I was cutting the outer edge, I ran into the steel bolt that held the tool plate to the mill table. The mill was programmed to eat through aluminum, when it hit the steel it really got annoyed at me ;) In any case I like the results. I have to lap the surface of the block down because the O-ring channel is just a hair too deep.

Attached Image(s)

|

DraginElite

CLASSIFIED Member

- Total Posts : 2706

- Reward points : 0

- Joined: 2008/05/01 18:47:28

- Location: My Own Little Corner

- Status: offline

- Ribbons : 17

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 08:27:49

(permalink)

ouch on the deal getting annoyed at you ... looking great though ... your game is really stepping up from the earlier gens of waterblocks you have made in the past

time to start incorporating or possibly LLC? :P

|

texinga

CLASSIFIED ULTRA Member

- Total Posts : 5066

- Reward points : 0

- Joined: 2010/07/03 14:30:32

- Status: offline

- Ribbons : 22

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 10:46:32

(permalink)

Thanks! I have been sanding all morning, and its still not enough. I have lots of mass that I have to make disappear in order to get a good seal on the O-ring. Lesson learned.  Tell me more of this flame polishing. Sounds like I take a torch to the block for brief moments.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 10:52:43

(permalink)

Oh yea I forgot to mention - that center circle needs a screw to hold it to the bottom plate. May not be necessary with a copper top, but the plexi flexes way to much and doesn't make a good seal.

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 2008/04/10 23:48:15

- Location: traveler

- Status: offline

- Ribbons : 271

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 11:43:04

(permalink)

Yeah, I noticed that o-ring in the middle of the bottom plate. I was wondering what that was for.

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 11:51:04

(permalink)

that hole is for one of the mobo mount screws, for the NF200's. I don't think copper would need a screw to hold it together because that aluminum one I made sealed up very nicely. I made the channel a bit too deep in this copper one, so im STILL lapping the entire block down to equal a shallower channel.

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 14:32:53

(permalink)

nateman_doo

Tell me more of this flame polishing. Sounds like I take a torch to the block for brief moments.

yep, quite simple really, just use map gas or propain torch and touch the edges with it. just practice a little first to get the hang of it. you will need to have the surface relativly smooth b4 you do it. It wont take out 1/64th milling marks(you still need to sand those), but it will change a cloudy cut to a glass clear one.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

RBIEZE

CLASSIFIED Member

- Total Posts : 3072

- Reward points : 0

- Joined: 2007/02/21 00:13:33

- Location: Northern Illinois...lurking in the Corn

- Status: offline

- Ribbons : 12

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 20:30:22

(permalink)

Good job Nate, wish I had the time to try my hand at making one. Looking forward to when its out of the beta stage and in limited production. !!! Congrats young Jedi. Edit...Oh by the way, I dry machine all my polycarbonate and acrylic tops. also You may want to consider putting the O-ring slot in the top, its easier to machine and of course much faster /less production time. I coded my new waterblock design that way, and the prototype "machine grade" Delrin top came out very well. 3 or 4 flute endmill, 1600 Rpm's and 10-15 IPM feedrate, with a final pass feedrate at 1.5 Ipm for a glass smooth finish.

post edited by RBIEZE - 2011/04/28 20:41:12

They say opposites attract. I hope you meet someone who is good-looking, intelligent, and cultured. http://www.youtube.com/watch?v=W2WsPN-rr9o Evga X58 4Way sli,W'Cooled i7 950 @3.8, Mushkin redline mem @6-7-6-18 1600Mhz, 2-Evga GTX770 Sli, Evga Gtx460 Physx, Corsair Neutron 120GB SSD,Samsung 240SSD, W.D Black 640GB /Corsair TX950 Psu, Hanns-G 28" Lcd, Logitech G540 5.1 Surround My Affiliate Code: EECLVEDV7Z

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 21:17:43

(permalink)

I think my machine eats through plastic, but I used the flood coolant because I didn't want everything heating up and melting. I didn't use it for the drilling cycle, and while it did power through the plastic, there was a solid coating of melted plastic on the bit when I went back down to check on the machine.

|

RBIEZE

CLASSIFIED Member

- Total Posts : 3072

- Reward points : 0

- Joined: 2007/02/21 00:13:33

- Location: Northern Illinois...lurking in the Corn

- Status: offline

- Ribbons : 12

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 21:27:03

(permalink)

Ugg, that sucks, havent had that problem , but our machines and tooling are different...are you running carbide tooling ??? Didnt mean to second guess you, just trying to be helpfull  .

They say opposites attract. I hope you meet someone who is good-looking, intelligent, and cultured. http://www.youtube.com/watch?v=W2WsPN-rr9o Evga X58 4Way sli,W'Cooled i7 950 @3.8, Mushkin redline mem @6-7-6-18 1600Mhz, 2-Evga GTX770 Sli, Evga Gtx460 Physx, Corsair Neutron 120GB SSD,Samsung 240SSD, W.D Black 640GB /Corsair TX950 Psu, Hanns-G 28" Lcd, Logitech G540 5.1 Surround My Affiliate Code: EECLVEDV7Z

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 22:27:54

(permalink)

If you want to try dry cutting acrylic. Use an upcut plastic flute bit that way it shoots the chips out of the way before they melt. In holes it is always tricky, need to slow the spindle speed way down and speed up the drop rate a little. can also shoot compressed air to cool the bit. thats what i do on my router. Its amazing the diferance the angle grind on the flute makes

post edited by Gratuitous - 2011/04/28 22:33:45

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/04/28 23:56:05

(permalink)

I try to run carbide all the time. For some reason I can't get HSS bits to work properly in my mill. I think the Z gibbs are loose and I am to tired to check. Will do in the AM.

|

Tobit

Superclocked Member

- Total Posts : 171

- Reward points : 0

- Joined: 2007/12/03 09:18:42

- Location: New Hampshire

- Status: offline

- Ribbons : 0

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 06:17:25

(permalink)

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 11:06:00

(permalink)

All the blocks are cut, drilled and tapped. I am sanding, counterboring, and awaiting a shipment of O-rings. I hope to have all the detail work done by the time the O-rings come.

I recently acquired a sandblaster. I was curious if anyone wanted a "frosted" finish to their block. I will blast a chunk of copper, coat it and take some pictures to show you guys what it looks like. Maybe some will like the finish?

|

Gratuitous

FTW Member

- Total Posts : 1109

- Reward points : 0

- Joined: 2011/03/16 04:30:23

- Location: California

- Status: offline

- Ribbons : 4

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 12:14:29

(permalink)

sounds like you are going to need to build a bigger basement  . we have a couple of sand blasters in the shop. very nice for all kinds of things. It might look interesting on the copper.

“I built a castle in the swamp and it sunk. I built a second castle and it sunk too. I built a third castle and it burned down and then sunk. But the fourth castle, Ahhhh! That one stood.” —Monty Python and the Holy Grail

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 12:18:23

(permalink)

using glass beads, as fine as powder. Looks very similar to a Danger Den block.

Yes, going to need a bigger basement, OR just take the rest of my basement back over

|

muskie32

CLASSIFIED Member

- Total Posts : 3026

- Reward points : 0

- Joined: 2010/11/20 17:09:06

- Location: I'd tell you a UDP joke but you might not get it

- Status: offline

- Ribbons : 23

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 12:36:08

(permalink)

Are you just planning on doing SR-2 blocks?

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 13:02:00

(permalink)

|

chrisj4040

FTW Member

- Total Posts : 1075

- Reward points : 0

- Joined: 2010/10/19 19:32:40

- Location: Arkansas (Why yes! We do have computers.)

- Status: offline

- Ribbons : 7

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 15:52:08

(permalink)

nateman_doo

All the blocks are cut, drilled and tapped. I am sanding, counterboring, and awaiting a shipment of O-rings. I hope to have all the detail work done by the time the O-rings come.

I recently acquired a sandblaster. I was curious if anyone wanted a "frosted" finish to their block. I will blast a chunk of copper, coat it and take some pictures to show you guys what it looks like. Maybe some will like the finish?

Finishing up as I type! They're on their way, promise!

Huginn Huginn -Asus P6T7 Supercomputer - core i7-950 @ 4.0 GHz - 3x4GB Corsair Dominator 1600C9 - Crucial C300 128 GB SSD - Corsair X128 128 GB SSD - 2x 1TB WD Caviar Black HDD - 3Way SLI eVGA GTX 480 Superclocked+ - Corsair H70 - Corsair AX1200 PSU - Thermaltake Armor+

|

Tobit

Superclocked Member

- Total Posts : 171

- Reward points : 0

- Joined: 2007/12/03 09:18:42

- Location: New Hampshire

- Status: offline

- Ribbons : 0

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 16:41:33

(permalink)

Polished copper with clear coat is all I want. :)

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 16:43:15

(permalink)

brushed finish? like the pics right?

|

Tobit

Superclocked Member

- Total Posts : 171

- Reward points : 0

- Joined: 2007/12/03 09:18:42

- Location: New Hampshire

- Status: offline

- Ribbons : 0

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 16:47:32

(permalink)

nateman_doo

brushed finish? like the pics right?

Yes sir, like the first pic on the front page.

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 17:29:00

(permalink)

OK. I thought you meant mirror finish. That would take a very long time to do ;)

|

nateman_doo

Omnipotent Enthusiast

- Total Posts : 8452

- Reward points : 0

- Joined: 2008/01/16 16:16:54

- Location: NOT the Jersey shore

- Status: offline

- Ribbons : 56

Re:100% Copper SR2 full coverage waterblock!

2011/05/06 22:14:26

(permalink)

First run of sandblasting:  This is my first time turning it on. It leaves a uniform surface just aching to be clear coated. Really looks sharp. I am sure my cell camera is doing it NO justice. This was just done after 80 grit sanded. Its almost like gravel. Here is a close-up of 40 grit, and also how well the pieces mesh together when put side by side:  As close to perfect as I can get at the moment. The holes in the picture have not been counterbored. They are all counterbored now.

|