bcavnaugh

The Crunchinator

- Total Posts : 38516

- Reward points : 0

- Joined: 2012/09/18 17:31:18

- Location: USA Affiliate E5L3CTGE12 Associate 9E88QK5L7811G3H

- Status: offline

- Ribbons : 282

Re: Kingpin Hydro copper temps.

2019/06/28 20:39:06

(permalink)

I have a Better Word than "ugh" but cannot post it here.  "I feel like a won a prize one when disconnects correctly." 90% of mine do work as they should.

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/28 21:34:09

(permalink)

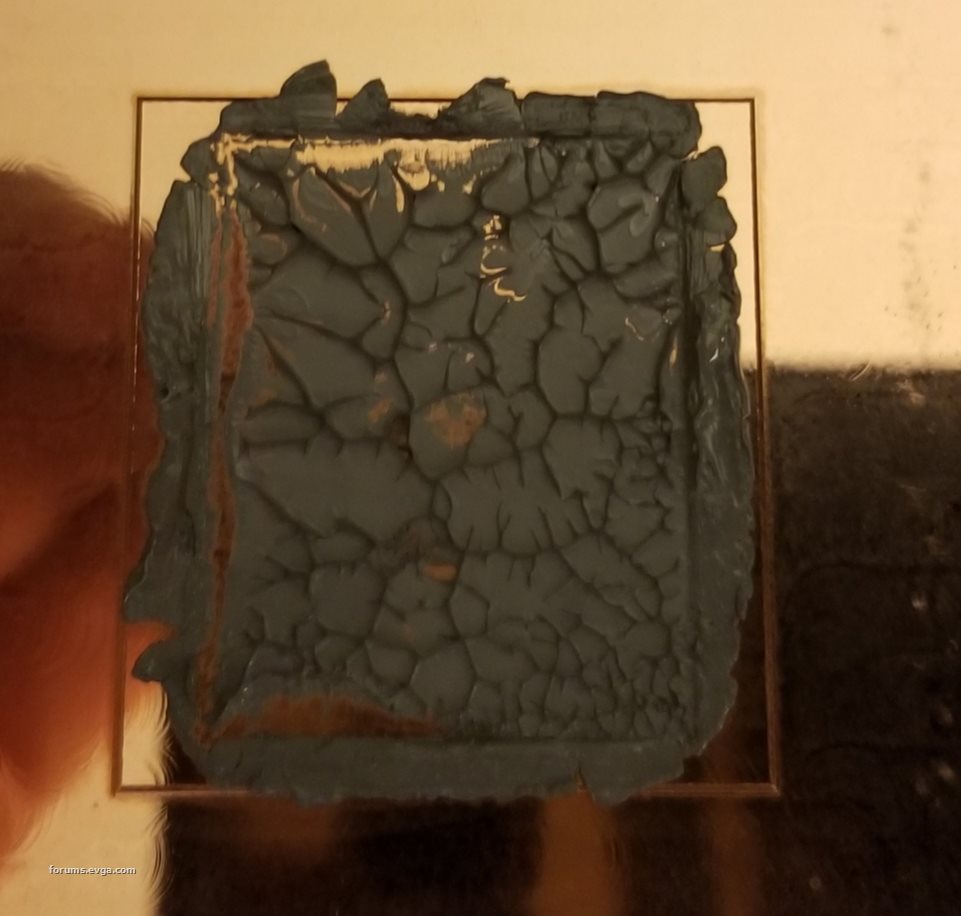

Seems to be a contact problem with the actual GPU die. After removing my AiO the spread pattern was amazing. Could clearly see the outline of the die in the TIM. After removing the waterblock it looks like one of the earlier pictures. This is with the new block as well. I wonder if some of these blocks have bad clearance?

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/28 21:37:13

(permalink)

Here are the comparisons. I tried to reseat it 3 times in a row to see if I could get a better pattern. And suggestions?

Attached Image(s)

|

bcavnaugh

The Crunchinator

- Total Posts : 38516

- Reward points : 0

- Joined: 2012/09/18 17:31:18

- Location: USA Affiliate E5L3CTGE12 Associate 9E88QK5L7811G3H

- Status: offline

- Ribbons : 282

Re: Kingpin Hydro copper temps.

2019/06/28 21:55:29

(permalink)

This is because you are not using the Spread Method

|

bp7178

iCX Member

- Total Posts : 373

- Reward points : 0

- Joined: 2016/04/15 15:24:51

- Status: offline

- Ribbons : 3

Re: Kingpin Hydro copper temps.

2019/06/28 22:37:09

(permalink)

bcavnaugh

Got it

Give the Card a good burn in for 48 Hours running Moo! Without Any OC and without running PX1 or MSI AB.

Just let it go on it's own and write the Current GPU PCB Temp and Mem1 Temp down from the OLED.

Then Check the same in two days time. You will need to make sure the Room Temperature Stays the Same.

I'm sorry if I missed it, but what thermal paste are you using? Are you using the supplied thermal pads or aftermarket? Is your card mounted horizontal or vertical? I really want to plastiguage the GPU, Mem and VRM and see how much clearance there is between them and the HC block and stock AIO cooler.

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/28 22:56:58

(permalink)

bp7178

bcavnaugh

Got it

Give the Card a good burn in for 48 Hours running Moo! Without Any OC and without running PX1 or MSI AB.

Just let it go on it's own and write the Current GPU PCB Temp and Mem1 Temp down from the OLED.

Then Check the same in two days time. You will need to make sure the Room Temperature Stays the Same.

I'm sorry if I missed it, but what thermal paste are you using?

Are you using the supplied thermal pads or aftermarket?

Is your card mounted horizontal or vertical?

I really want to plastiguage the GPU, Mem and VRM and see how much clearance there is between them and the HC block and stock AIO cooler.

I'm using the stock thermal pads, Tim that came with it and mounted horizontally.

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/28 22:58:31

(permalink)

bcavnaugh

This is because you are not using the Spread Method

I used the same method on both and they look completely different. Try again.

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 06:46:36

(permalink)

zurvv

warning.. be prepared for ghetto :)

setup, this is a TV gaming PC. I'm replacing 2080 ti SLI (bitspower blocks) with KPE.

(it is a small case! :) It has to fit in a AV cabinet and look good.)

I'm been having issues both with flow and temp of the second card.

I don't think the card likes being feed from the sides. I tried parallel as you'd expect and the second card got very hot. The flow dropped from 8lpm to 3. I tried serial and the temps were fine-ish, but the flow dropped to 1.5lpm. (ugh)

So i ghetto'd this parallel. :) Coming in from the top of the card vs the sides, and using a y spiller. Flow still isn't great (over 5lpm), but much better. Temps a bit higher than i'd expect, but i think that is because of the flow. ~48C on both cards on Port Royal with +125 core and +1400 ram. I took the water sensor out, but i'll add it back in later. Room temp is about 25C.

Anyone else in SLI? Are the HC cards more flow restrictive than most? (i normally use bitspower and EK.)

I have a gillion Koolance quick disconnects that i'm sure aren't helping. I'll take some of them out and maybe add another pump. :)

(I did beat my old port royal score with these.. which was cool as i wasn't trying to push the cards. Moving up higher in the 100s. (blah i used to be in the top ten.) My other system is in my sig. So it beat Titan RTXs and higher OC'd CPU with more cores. (not that port royal cares about those.)

Yeah those HC blocks are restrictive! Last night I figured i finished adding in dual EK D5 serial pump tops (4 pumps total) and another rad (EK 560 SE.. 5 rads total 2x EK XE 480,2x XE 360 All push/Pull and EK 560 SE Push fans. Temps maybe dropped 2c.. seen mostly 36c GPU temps benching at 70f. Water flow dont look any different from before with dual d5 pumps.. looking at the ek 260mm res I dont see the liquid moving at all. I know it is from watching the bubbles but that's it. Anyways before this all with dual loops and a ek GPU block and a ek Velocity block.. the velocity block had real slow movement in the res and the ek block had lots of water movement in the res.. now when I first switched to the HC block thr water movement was calm and the CPU block was faster! Haha So these HC blocks are really restrictive from what I can tell.

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

bcavnaugh

The Crunchinator

- Total Posts : 38516

- Reward points : 0

- Joined: 2012/09/18 17:31:18

- Location: USA Affiliate E5L3CTGE12 Associate 9E88QK5L7811G3H

- Status: offline

- Ribbons : 282

Re: Kingpin Hydro copper temps.

2019/06/29 07:08:13

(permalink)

bp7178

bcavnaugh

Got it

Give the Card a good burn in for 48 Hours running Moo! Without Any OC and without running PX1 or MSI AB.

Just let it go on it's own and write the Current GPU PCB Temp and Mem1 Temp down from the OLED.

Then Check the same in two days time. You will need to make sure the Room Temperature Stays the Same.

I'm sorry if I missed it, but what thermal paste are you using?

Are you using the supplied thermal pads or aftermarket?

Is your card mounted horizontal or vertical?

I really want to plastiguage the GPU, Mem and VRM and see how much clearance there is between them and the HC block and stock AIO cooler.

stock thermal pads and TF8 Thermal Paste. Horizontal Yea a Filler Gage would be hard to use, never though about a Plastiguage

|

bcavnaugh

The Crunchinator

- Total Posts : 38516

- Reward points : 0

- Joined: 2012/09/18 17:31:18

- Location: USA Affiliate E5L3CTGE12 Associate 9E88QK5L7811G3H

- Status: offline

- Ribbons : 282

Re: Kingpin Hydro copper temps.

2019/06/29 07:24:36

(permalink)

Jahusaphet

bcavnaugh

This is because you are not using the Spread Method

I used the same method on both and they look completely different. Try again.

If this was the Spread Method then the Corners of Square would also be covered. The Image above shows you did not use the Spread Method on the HC Water Block is all. So why are you saying "Try Again" Try What Again? "get a better pattern" You have not Posted the Method you used or Pattern Used in your above Post. It is not a guessing game here. But my Guess is you appalled Thermal Paste only the GPU Die, how is anyone's guess. I not talking about the Hybrid Pump or how it looks or how you applied your Thermal Paste to it, it is not in question here.  By the Way My HC Water Block Square looked more like this. This has full coverage.  Jahusaphet Jahusaphet I know this is your Thread but we are all trying to help each other as well. We are still waiting for you to post a snapshot or image of your PX1 iCX Settings Showing the Temperatures as show below using the same Settings to compare yours KPE HC Water Block.   Forgot about this Image.

post edited by bcavnaugh - 2019/06/29 12:11:17

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/29 09:29:56

(permalink)

Its been proven time and time again that the way you apply thermal paste has little to no effect. Also I wasn't posting it to have the application questioned or nitpicked. I was showing how well the spread was on the AiO compared to the waterblock with the same application. "Try again" was because I feel like half the answers i get on here are about thermal paste when that's not the issue here.

The hydro copper isnt making good contact. What would a picture of my ICX show? That my card isnt making good contact and I'm getting the temps I stated? If I use a mountain of thermal paste of course the spread is going to "look" better there's too much and it's still isnt making good contact as half the people in this thread stated multiple times.

If you have any suggestions as to why it's not seated properly I'll thank you for it. But commenting on my post that says I dont think its seated properly with "you didnt use the spread method" feel more like I'm being trolled than helped.

|

sparetimepc

CLASSIFIED Member

- Total Posts : 2413

- Reward points : 0

- Joined: 2009/11/13 09:24:09

- Location: Altona, IL

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 09:51:37

(permalink)

Jahusaphet

Its been proven time and time again that the way you apply thermal paste has little to no effect. Also I wasn't posting it to have the application questioned or nitpicked. I was showing how well the spread was on the AiO compared to the waterblock with the same application. "Try again" was because I feel like half the answers i get on here are about thermal paste when that's not the issue here.

The hydro copper isnt making good contact. What would a picture of my ICX show? That my card isnt making good contact and I'm getting the temps I stated? If I use a mountain of thermal paste of course the spread is going to "look" better there's too much and it's still isnt making good contact as half the people in this thread stated multiple times.

If you have any suggestions as to why it's not seated properly I'll thank you for it. But commenting on my post that says I dont think its seated properly with "you didnt use the spread method" feel more like I'm being trolled than helped.

Do like i did, remove all thermal pads from the block and then put on your thermal paste and tighten down the block, thats how i determined that the thermal pads were to thick on the memory. When i removed them and had much better contact then i realized the memory pads were to thick and i went to the 1.0mm instead of the 1.25mm. Mine was the same way, the spread pattern was not very good at all until i used thinner pads on the memory. My oem AIO that it cam with fit excellent and had great squeeze out, the block wasn't good at all as far as i'm concerned.

post edited by dwexpress - 2019/06/29 09:53:42

|

bcavnaugh

The Crunchinator

- Total Posts : 38516

- Reward points : 0

- Joined: 2012/09/18 17:31:18

- Location: USA Affiliate E5L3CTGE12 Associate 9E88QK5L7811G3H

- Status: offline

- Ribbons : 282

Re: Kingpin Hydro copper temps.

2019/06/29 10:04:11

(permalink)

Jahusaphet

Its been proven time and time again that the way you apply thermal paste has little to no effect. Also I wasn't posting it to have the application questioned or nitpicked. I was showing how well the spread was on the AiO compared to the waterblock with the same application. "Try again" was because I feel like half the answers i get on here are about thermal paste when that's not the issue here.

The hydro copper isnt making good contact. What would a picture of my ICX show? That my card isnt making good contact and I'm getting the temps I stated? If I use a mountain of thermal paste of course the spread is going to "look" better there's too much and it's still isnt making good contact as half the people in this thread stated multiple times.

If you have any suggestions as to why it's not seated properly I'll thank you for it. But commenting on my post that says I dont think its seated properly with "you didnt use the spread method" feel more like I'm being trolled than helped.

I have only been Asking if that was the Method Used, You have yet Stated what the Method is you are using. I will start from the Top and re-read the Thread. "What would a picture of my ICX show?" This would Show us all your Temperatures "I dont think its seated properly" You have never stated this before this Post #191 or have ever ask this question before. Also I never posted that you did or did not have it seated properly or comment about it. You did post this Jahusaphet I reseated it 8 times so I dont think it's my placement.

And this, But you never asked or posted "But commenting on my post that says I dont think its seated properly" Jahusaphet

Here are the comparisons. I tried to reseat it 3 times in a row to see if I could get a better pattern. And suggestions?

But I will pull back as I do not want you to think that I am Trolling You. Best of luck with your issues.

post edited by bcavnaugh - 2019/06/29 10:43:42

|

zurvv

iCX Member

- Total Posts : 405

- Reward points : 0

- Joined: 2007/08/22 09:12:16

- Location: NYC

- Status: offline

- Ribbons : 2

Re: Kingpin Hydro copper temps.

2019/06/29 11:40:29

(permalink)

AHowes

zurvv

warning.. be prepared for ghetto :)

setup, this is a TV gaming PC. I'm replacing 2080 ti SLI (bitspower blocks) with KPE.

(it is a small case! :) It has to fit in a AV cabinet and look good.)

I'm been having issues both with flow and temp of the second card.

I don't think the card likes being feed from the sides. I tried parallel as you'd expect and the second card got very hot. The flow dropped from 8lpm to 3. I tried serial and the temps were fine-ish, but the flow dropped to 1.5lpm. (ugh)

So i ghetto'd this parallel. :) Coming in from the top of the card vs the sides, and using a y spiller. Flow still isn't great (over 5lpm), but much better. Temps a bit higher than i'd expect, but i think that is because of the flow. ~48C on both cards on Port Royal with +125 core and +1400 ram. I took the water sensor out, but i'll add it back in later. Room temp is about 25C.

Anyone else in SLI? Are the HC cards more flow restrictive than most? (i normally use bitspower and EK.)

I have a gillion Koolance quick disconnects that i'm sure aren't helping. I'll take some of them out and maybe add another pump. :)

(I did beat my old port royal score with these.. which was cool as i wasn't trying to push the cards. Moving up higher in the 100s. (blah i used to be in the top ten.) My other system is in my sig. So it beat Titan RTXs and higher OC'd CPU with more cores. (not that port royal cares about those.)

Yeah those HC blocks are restrictive!

Last night I figured i finished adding in dual EK D5 serial pump tops (4 pumps total) and another rad (EK 560 SE.. 5 rads total 2x EK XE 480,2x XE 360 All push/Pull and EK 560 SE Push fans.

Temps maybe dropped 2c.. seen mostly 36c GPU temps benching at 70f.

Water flow dont look any different from before with dual d5 pumps.. looking at the ek 260mm res I dont see the liquid moving at all. I know it is from watching the bubbles but that's it.

Anyways before this all with dual loops and a ek GPU block and a ek Velocity block.. the velocity block had real slow movement in the res and the ek block had lots of water movement in the res.. now when I first switched to the HC block thr water movement was calm and the CPU block was faster! Haha

So these HC blocks are really restrictive from what I can tell.

How are you connecting to the block? From the side or the top? i think from the side might not be super friendly. That said, i'm only testing with SLI and it was x2 more flow when doing my ghetto Y splitter. See the pix below on my expreince. (for a pump i'm using a EK d5 and whatever pump is in the koolance. ( https://koolance.com/erm-3k3uc-liquid-cooling-system-copper) I'm running tubes out of the case so this setup has a little more tubing that one would expect. I'm also cooling a i9-7900x with a Koolance CPU-i400 block. (which i really like.)  the setup:  I've not really done much OC'n yet with the system. But i did some quick port royal tests yesterday. (HOF #28 for 2 cards - http://www.3dmark.com/pr/109247 ) temps where under 50-ish. (if i recall - but the fans where running really high.)

post edited by zurvv - 2019/06/29 11:44:49

EVGA RTX 3090 FTW3 (water cooled), LG OLED77G1 TV (77")i9-12900KF 5.5ghz (water cooled), Asus z690 Apex32gig DDR5 6000mhz, Corsair 1600 Watt PSUSamsung 980 pro 2gig NVMe and Samsung 980 pro 1gig NVMeWindows 11 Pro x64 (21H2)Logitech Harmony Ultimate remote, Xbox Elite 2 Controller

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 12:07:56

(permalink)

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

zurvv

iCX Member

- Total Posts : 405

- Reward points : 0

- Joined: 2007/08/22 09:12:16

- Location: NYC

- Status: offline

- Ribbons : 2

Re: Kingpin Hydro copper temps.

2019/06/29 12:12:56

(permalink)

AHowes

Single card so...

but you can connect it from the top or side. I found the top better (at least for SLI.) Going by others, that seem to be happy with their perf, they are connecting from the top of the block. Which are you connecting to? From the top the water doesn't have to make a 90 turn. (or maybe it makes no diff at all :) )

EVGA RTX 3090 FTW3 (water cooled), LG OLED77G1 TV (77")i9-12900KF 5.5ghz (water cooled), Asus z690 Apex32gig DDR5 6000mhz, Corsair 1600 Watt PSUSamsung 980 pro 2gig NVMe and Samsung 980 pro 1gig NVMeWindows 11 Pro x64 (21H2)Logitech Harmony Ultimate remote, Xbox Elite 2 Controller

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/29 12:14:55

(permalink)

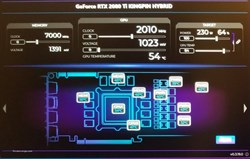

Here is the card with heaven running in the background. All is at default. As you can see everything else seems to have pretty decent temps except for the core.

Attached Image(s)

|

Jahusaphet

Superclocked Member

- Total Posts : 157

- Reward points : 0

- Joined: 2017/03/04 03:20:24

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/06/29 12:44:57

(permalink)

bcavnaugh

Jahusaphet

Its been proven time and time again that the way you apply thermal paste has little to no effect. Also I wasn't posting it to have the application questioned or nitpicked. I was showing how well the spread was on the AiO compared to the waterblock with the same application. "Try again" was because I feel like half the answers i get on here are about thermal paste when that's not the issue here.

The hydro copper isnt making good contact. What would a picture of my ICX show? That my card isnt making good contact and I'm getting the temps I stated? If I use a mountain of thermal paste of course the spread is going to "look" better there's too much and it's still isnt making good contact as half the people in this thread stated multiple times.

If you have any suggestions as to why it's not seated properly I'll thank you for it. But commenting on my post that says I dont think its seated properly with "you didnt use the spread method" feel more like I'm being trolled than helped.

I have only been Asking if that was the Method Used, You have yet Stated what the Method is you are using.

I will start from the Top and re-read the Thread. "What would a picture of my ICX show?" This would Show us all your Temperatures

"I dont think its seated properly" You have never stated this before this Post #191 or have ever ask this question before.

Also I never posted that you did or did not have it seated properly or comment about it.

You did post this

Jahusaphet I reseated it 8 times so I dont think it's my placement.

And this, But you never asked or posted "But commenting on my post that says I dont think its seated properly"

Jahusaphet

Here are the comparisons. I tried to reseat it 3 times in a row to see if I could get a better pattern. And suggestions?

But I will pull back as I do not want you to think that I am Trolling You.

Best of luck with your issues.

You didnt ask a single question about the spread pattern. You made a statement "This is because you didnt use the spread method". Right above the post with the pictures I clearly state that I believe its a contact issue with the actual die. I dont know how much clearer I can get. Post #183 "Seems to be a contact problem with the actual GPU die. After removing my AiO the spread pattern was amazing. Could clearly see the outline of the die in the TIM. After removing the waterblock it looks like one of the earlier pictures. This is with the new block as well. I wonder if some of these blocks have bad clearance?" Your answer was not an answer at all to the question asked. Like I stated earlier I appreciate people trying to help, but you didn't actually answer my question you simply commented on my thermal paste application.

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 13:16:22

(permalink)

zurvv

AHowes

Single card so...

but you can connect it from the top or side. I found the top better (at least for SLI.) Going by others, that seem to be happy with their perf, they are connecting from the top of the block.

Which are you connecting to? From the top the water doesn't have to make a 90 turn. (or maybe it makes no diff at all :) )

Connected from the left bottom in and out the top right.

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 13:38:30

(permalink)

Here is the updated build.. My wife seen it last night for the first time and she says it's the ugliest thing she ever seen! Lol.. so that means its awesome! https://imgur.com/a/nsYxIJx

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 13:42:58

(permalink)

The tip about the memory pads is interesting and I wouldn't mind trying it out in the future. Just point me in the direction for the best 1mm thermal pads.

Might use the GPU bracket next time as I bet it was designed to help increase mounting pressure atleast now that I think about it. Doing the combo sounds like a nice few degrees in the right direction.

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 2010/04/19 22:23:25

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Kingpin Hydro copper temps.

2019/06/29 14:41:50

(permalink)

zurvv

AHowes

zurvv

warning.. be prepared for ghetto :)

setup, this is a TV gaming PC. I'm replacing 2080 ti SLI (bitspower blocks) with KPE.

(it is a small case! :) It has to fit in a AV cabinet and look good.)

I'm been having issues both with flow and temp of the second card.

I don't think the card likes being feed from the sides. I tried parallel as you'd expect and the second card got very hot. The flow dropped from 8lpm to 3. I tried serial and the temps were fine-ish, but the flow dropped to 1.5lpm. (ugh)

So i ghetto'd this parallel. :) Coming in from the top of the card vs the sides, and using a y spiller. Flow still isn't great (over 5lpm), but much better. Temps a bit higher than i'd expect, but i think that is because of the flow. ~48C on both cards on Port Royal with +125 core and +1400 ram. I took the water sensor out, but i'll add it back in later. Room temp is about 25C.

Anyone else in SLI? Are the HC cards more flow restrictive than most? (i normally use bitspower and EK.)

I have a gillion Koolance quick disconnects that i'm sure aren't helping. I'll take some of them out and maybe add another pump. :)

(I did beat my old port royal score with these.. which was cool as i wasn't trying to push the cards. Moving up higher in the 100s. (blah i used to be in the top ten.) My other system is in my sig. So it beat Titan RTXs and higher OC'd CPU with more cores. (not that port royal cares about those.)

Yeah those HC blocks are restrictive!

Last night I figured i finished adding in dual EK D5 serial pump tops (4 pumps total) and another rad (EK 560 SE.. 5 rads total 2x EK XE 480,2x XE 360 All push/Pull and EK 560 SE Push fans.

Temps maybe dropped 2c.. seen mostly 36c GPU temps benching at 70f.

Water flow dont look any different from before with dual d5 pumps.. looking at the ek 260mm res I dont see the liquid moving at all. I know it is from watching the bubbles but that's it.

Anyways before this all with dual loops and a ek GPU block and a ek Velocity block.. the velocity block had real slow movement in the res and the ek block had lots of water movement in the res.. now when I first switched to the HC block thr water movement was calm and the CPU block was faster! Haha

So these HC blocks are really restrictive from what I can tell.

How are you connecting to the block? From the side or the top? i think from the side might not be super friendly. That said, i'm only testing with SLI and it was x2 more flow when doing my ghetto Y splitter.

See the pix below on my expreince. (for a pump i'm using a EK d5 and whatever pump is in the koolance. (https://koolance.com/erm-3k3uc-liquid-cooling-system-copper) I'm running tubes out of the case so this setup has a little more tubing that one would expect. I'm also cooling a i9-7900x with a Koolance CPU-i400 block. (which i really like.)

the setup:

I've not really done much OC'n yet with the system. But i did some quick port royal tests yesterday. (HOF #28 for 2 cards - http://www.3dmark.com/pr/109247 )

temps where under 50-ish. (if i recall - but the fans where running really high.)

Ahowes is right about the blocks being restrictive. I went from two GTX 780 Classifieds HCs (Swiftech) to one RTX 2080 Ti Black HC (In house design) and it's more restrictive. lol There was even a review a while back about their 1080 HC (In house design) on how restrictive it was when EVGA used to get less restrictive GPU WBs from reputed WB brands like Swiftech and EK prior. I must say, that's the oddest Parallel configuration I've seen but hey if it works, it works. What you did here is force the flow down the channel of the block exactly where it's positioned versus going from the top or bottom of the GPU ports as most of us have set, forcing the flow to cut 90 degree which adds to the restrictive equation. Not a bad idea I must say now that I've thought about it more. heh AHowes

Here is the updated build..

My wife seen it last night for the first time and she says it's the ugliest thing she ever seen! Lol.. so that means its awesome!

https://imgur.com/a/nsYxIJx

She's a beauty, GTXJackBauer's Approval you tell her!  AHowes

The tip about the memory pads is interesting and I wouldn't mind trying it out in the future. Just point me in the direction for the best 1mm thermal pads.

Might use the GPU bracket next time as I bet it was designed to help increase mounting pressure atleast now that I think about it. Doing the combo sounds like a nice few degrees in the right direction.

Can't go wrong with 17/K Fujipoly. Pricey but it's some of the best stuff out there.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 16:22:59

(permalink)

GTXJackBauer

Can't go wrong with 17/K Fujipoly. Pricey but it's some of the best stuff out there.

Thanks!

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|

bp7178

iCX Member

- Total Posts : 373

- Reward points : 0

- Joined: 2016/04/15 15:24:51

- Status: offline

- Ribbons : 3

Re: Kingpin Hydro copper temps.

2019/06/29 17:03:06

(permalink)

dwexpress

Do like i did, remove all thermal pads from the block and then put on your thermal paste and tighten down the block, thats how i determined that the thermal pads were to thick on the memory. When i removed them and had much better contact then i realized the memory pads were to thick and i went to the 1.0mm instead of the 1.25mm. Mine was the same way, the spread pattern was not very good at all until i used thinner pads on the memory. My oem AIO that it cam with fit excellent and had great squeeze out, the block wasn't good at all as far as i'm concerned.

This was almost exactly what I was thinking, that there is a clearance issue somewhere. I think the TIM spread issues (lack of spread) are related to the final clearance between the GPU die and HC block. So it makes sense using thinner pads would allow the HC block to sit lower and thereby exert more pressure causing the TIM to spread. I wasn't aware that the stock HC pads were 1.25mm, I thought they were 1.0mm, but I only measured mine after I had already installed the block though. Not with a dial caliper or anything mind you, just a ruler. Did you change the size of the VRM and inductor pads as well? I was going to order some 1.0mm pads, but now I want to check with some .5mm pads as well. I have a bunch of EK pads at home in the 1.0mm flavor, but I may order some Thermal Grizzly or Fuji ones cause reasons. With all the theories about TIM application, the only sins I feel are applying too little, and having too much of a gap between the IHS/die and cold plate when mounting the cooler. I've always applied TIM according to the manufactures instructions. With Thermal Grizzly Kryonaut, its the spread method using the flat rubber tip they give you. I have also noticed that with vertical GPUs if there too much clearance or insufficient mounting pressure between the GPU die and cold plate, the TIM can seep down when warmed up. If the whole die isn't covered or looses contact this can obviously be catastrophic.

|

sparetimepc

CLASSIFIED Member

- Total Posts : 2413

- Reward points : 0

- Joined: 2009/11/13 09:24:09

- Location: Altona, IL

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/06/29 17:29:50

(permalink)

bp7178

dwexpress

Do like i did, remove all thermal pads from the block and then put on your thermal paste and tighten down the block, thats how i determined that the thermal pads were to thick on the memory. When i removed them and had much better contact then i realized the memory pads were to thick and i went to the 1.0mm instead of the 1.25mm. Mine was the same way, the spread pattern was not very good at all until i used thinner pads on the memory. My oem AIO that it cam with fit excellent and had great squeeze out, the block wasn't good at all as far as i'm concerned.

This was almost exactly what I was thinking, that there is a clearance issue somewhere. I think the TIM spread issues (lack of spread) are related to the final clearance between the GPU die and HC block. So it makes sense using thinner pads would allow the HC block to sit lower and thereby exert more pressure causing the TIM to spread. I wasn't aware that the stock HC pads were 1.25mm, I thought they were 1.0mm, but I only measured mine after I had already installed the block though. Not with a dial caliper or anything mind you, just a ruler.

Did you change the size of the VRM and inductor pads as well? I was going to order some 1.0mm pads, but now I want to check with some .5mm pads as well. I have a bunch of EK pads at home in the 1.0mm flavor, but I may order some Thermal Grizzly or Fuji ones cause reasons.

With all the theories about TIM application, the only sins I feel are applying too little, and having too much of a gap between the IHS/die and cold plate when mounting the cooler. I've always applied TIM according to the manufactures instructions. With Thermal Grizzly Kryonaut, its the spread method using the flat rubber tip they give you.

I have also noticed that with vertical GPUs if there too much clearance or insufficient mounting pressure between the GPU die and cold plate, the TIM can seep down when warmed up. If the whole die isn't covered or looses contact this can obviously be catastrophic.

I kept 1.5mm pads everywhere except the memory, thats where i went from 1.25mm to 1.0mm pads. Also needed to take into consideration is the type of pads that are used, some pads are more easily squeezed then others, the fujipoly pads are a lot more firm so there is not as much give to them. The less give your pads have the more precise you will have to be with your thickness used.

|

sjcrespo

New Member

- Total Posts : 30

- Reward points : 0

- Joined: 2019/02/14 23:30:25

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/07/05 23:18:32

(permalink)

dwexpress

I kept 1.5mm pads everywhere except the memory, thats where i went from 1.25mm to 1.0mm pads. Also needed to take into consideration is the type of pads that are used, some pads are more easily squeezed then others, the fujipoly pads are a lot more firm so there is not as much give to them. The less give your pads have the more precise you will have to be with your thickness used. Late to the thread, just catching up. Are you using the Fujipoly or EK? Thanks.

post edited by sjcrespo - 2019/07/05 23:27:08

|

FROSTYBE3R

Superclocked Member

- Total Posts : 242

- Reward points : 0

- Joined: 2018/08/10 01:02:26

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/07/06 00:28:57

(permalink)

bcavnaugh

@ vladdimplr Compared to mine

Room 23.5°C Coolant 20.9°C

Seems quite high temperatures for 20c coolant, 2145MHz?

|

Vlada011

Omnipotent Enthusiast

- Total Posts : 10126

- Reward points : 0

- Joined: 2012/03/25 00:14:05

- Location: Belgrade-Serbia

- Status: offline

- Ribbons : 11

Re: Kingpin Hydro copper temps.

2019/07/06 04:20:06

(permalink)

Temperature of GPU need to be checked after confirmation that frequency in idle drop on minimum. Sometimes frequency of GPU stay high even in idle and temps are higher, customer think something is not right with cooling. Even installing thermal pad over GPU will help if contact is not best and drop temperature temperatures. Maybe is not good as thin layer of paste, but better then bad contact and could tell what is wrong. In idle in my PC and Power Mode on Balanced temperature of GPU and CPU Cores is absolutely same with 1-2C difference. When I change Power Mode on High Performance CPU Temp go up 4-5C. EK Slim radiators are very thin, even my EK PE radiator is almost same chamber as Black Ice Nemesis GTS. Chamber is much thinner then housing.

post edited by Vlada011 - 2019/07/06 04:25:44

|

FROSTYBE3R

Superclocked Member

- Total Posts : 242

- Reward points : 0

- Joined: 2018/08/10 01:02:26

- Status: offline

- Ribbons : 0

Re: Kingpin Hydro copper temps.

2019/07/06 04:30:11

(permalink)

Vlada011

Temperature of GPU need to be checked after confirmation that frequency in idle drop on minimum.

Sometimes frequency of GPU stay high even in idle and temps are higher, customer think something is not right with cooling.

Even installing thermal pad over GPU will help if contact is not best and drop temperature temperatures.

Maybe is not good as thin layer of paste, but better then bad contact and could tell what is wrong.

In idle in my PC and Power Mode on Balanced temperature of GPU and CPU Cores is absolutely same with 1-2C difference.

When I change Power Mode on High Performance CPU Temp go up 4-5C.

EK Slim radiators are very thin, even my EK PE radiator is almost same chamber as Black Ice Nemesis GTS.

Chamber is much thinner then housing.

???

|

AHowes

CLASSIFIED ULTRA Member

- Total Posts : 6502

- Reward points : 0

- Joined: 2005/09/20 15:38:10

- Location: Macomb MI

- Status: offline

- Ribbons : 27

Re: Kingpin Hydro copper temps.

2019/07/06 10:38:22

(permalink)

Got my thermal pads co.ing tomorrow.. went with 2x 60x50x 1.00mm and 1 60x50x1.5mm pad.

If I cut right I'll get 12 squares out of the larger pad for $8 more over the 15mmx100mm pad which would be about 7 cut squares.

Intel i9 9900K @ 5.2Ghz Single HUGE Custom Water Loop. Asus Z390 ROG Extreme XI MB G.Skill Trident Z 32GB (4x8GB) 4266MHz DDR4 EVGA 2080ti K|NGP|N w/ Hydro Copper block. 34" Dell Alienware AW3418DW 1440 Ultra Wide GSync Monitor Thermaltake Core P7 Modded w/ 2x EK Dual D5 pump top,2 x EK XE 480 2X 360 rads.1 Corsair 520 Rad.

|