warcobra

Superclocked Member

- Total Posts : 190

- Reward points : 0

- Joined: 5/24/2005

- Status: offline

- Ribbons : 1

Friday, November 03, 2017 3:32 AM

(permalink)

So I have been using a separate computer to control a Water Pump for testing and filling forever. I am now building more and more PC's for people and was wondering if anyone knows how to run a pump at PWM pump at max speed without plugging it into a PC with PWM to make it go full speed. I am just tired of pulling my PC up to my bench and hooking the PWM plug into the board while filling the loop. Thanks in advance.

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 4/11/2008

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Controlling a PWM Water Pump

Friday, November 03, 2017 4:55 AM

(permalink)

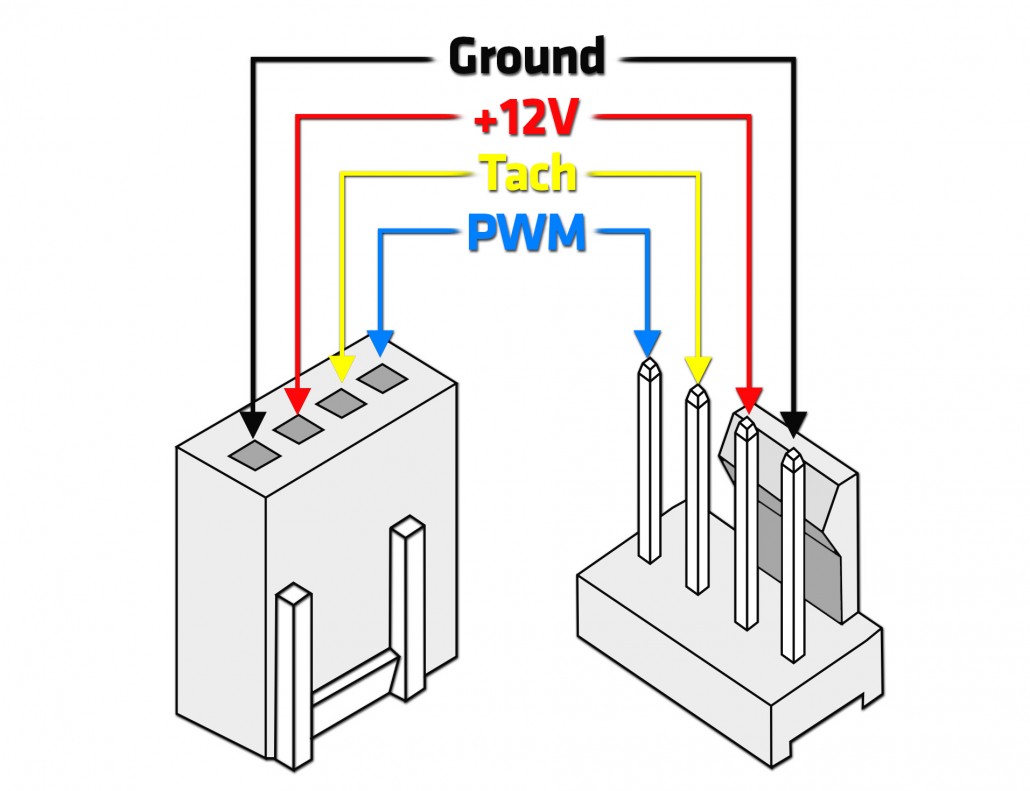

With the +12v power (usually red or yellow) wire connected to +12v power source, and the ground (usually black) wire connected to a ground wire, plug the PWM wire (usually blue or green) into a +12 +5v power source. Now it will run at 100%. Look at the pinout for a standard molex power connector. A standard molex power connector has a +12v and a +5v power source and that is all you will need. Make sure to leave the tach (usually yellow or green) wire disconnected; because powering or grounding the tachometer wire -- shouldn't, but -- may damage the pump.  It's a pretty safe bet to ignore the colors since who knows which wire colors your pump manufacture chose to use. Instead of paying attention to the wire colors, pay attention to the wire locations. Pin 1 is on the alignment tab end of the connector and is ground. Pin 2 is next to it which is +12v. Pin 3 is tachometer / signal feedback. Pin 4 is on the opposite end and is PWM digital control. The +12v power wire gives the pump power. The ground wire gives the power a return to ground. The PWM wire sets the duty cycle of the pump. If the PWM wire is connected to a constant +12 +5v source, its duty cycle is 100% and therefore the pump will run at full speed. Likewise, if you connect the PWM wire to ground, the pump will run at minimum speed. If you leave the PWM wire disconnected from either power or ground, some pumps run at minimum speed, some pumps run at maximum speed, and some pumps run at a predetermined speed somewhere in between. Connect the PWM wire up to a squarewave generator running at 25 kHz with a 50% duty cycle of +12 +5v and a 50% duty cycle of ground, and your pump will run at 50% speed.  http://img.techpowerup.org/171105/pumpfullspeed.png http://img.techpowerup.org/171105/pumpfullspeed.png

post edited by ty_ger07 - Sunday, November 05, 2017 0:36 PM

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

Cool GTX

EVGA Forum Moderator

- Total Posts : 31353

- Reward points : 0

- Joined: 12/12/2010

- Location: Folding for the Greater Good

- Status: offline

- Ribbons : 123

Re: Controlling a PWM Water Pump

Friday, November 03, 2017 4:05 PM

(permalink)

Moving to Overclocking, Cooling and Benchmarking

post edited by Cool GTX - Friday, November 03, 2017 4:26 PM

Learn your way around the EVGA Forums, Rules & limits on new accounts Ultimate Self-Starter Thread For New Members

I am a Volunteer Moderator - not an EVGA employee

Older RIG projects RTX Project Nibbler

When someone does not use reason to reach their conclusion in the first place; you can't use reason to convince them otherwise!

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Friday, November 03, 2017 11:38 PM

(permalink)

What specific pump are we talking about?

Dependent on the pump, if it comes with two pairs of wires, Yellow/Black for power from the PSU and Green/Blue for tach and PWM signal, you could just keep the Green/Blue wires disconnected and just have the power cables connected. That should give you 70%-100% speed by default.

In Ty_ger's diagram, in most if not all cases, that is for PWM Fans. PWM pumps usually come in two separate pairs of wires. They usually come in a single wire if it's voltage controlled.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

warcobra

Superclocked Member

- Total Posts : 190

- Reward points : 0

- Joined: 5/24/2005

- Status: offline

- Ribbons : 1

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 3:53 AM

(permalink)

The Specific Pump is a EK D5 REVO XRES140.

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 4:59 AM

(permalink)

warcobra

The Specific Pump is a EK D5 REVO XRES140.

Just plug in the molex power only. Should get the pump going and make sure it never runs dry as I'm sure you probably know that already.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 4/11/2008

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 8:09 PM

(permalink)

GTXJackBauer

warcobra

The Specific Pump is a EK D5 REVO XRES140.

Just plug in the molex power only. Should get the pump going and make sure it never runs dry as I'm sure you probably know that already.

Yes, but he wants to run it at full speed while leak checking a system without powering on that system or needing a second computer to increase the pump speed. Currently, he is plugging it into a second along-side computer header to increase the speed. His question was how to make the pump run full speed without plugging it into a computer's header. The answer, like I gave above, is that, in addition to plugging it into a molex plug, he needs to run a 12 5v wire from a molex plug over into the PWM wire. That is the quickest and easiest way to make it run full speed without needing a fan header or any other type of fan controller

post edited by ty_ger07 - Saturday, November 04, 2017 11:48 PM

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 10:19 PM

(permalink)

ty_ger07

Yes, but he wants to run it at full speed while leak checking a system without powering on that system or needing a second computer to increase the pump speed. Currently, he is plugging it into a second along-side computer header to increase the speed. His question was how to make the pump run full speed without plugging it into a computer's header. The answer, like I gave above, is that, in addition to plugging it into a molex plug, he needs to run a 12v wire from a molex plug over into the PWM wire. That is the quickest and easiest way to make it run full speed without needing a fan header or any other type of fan controller

No he doesn't unless he wants to damage his pump. OP, you are NOT going to connect a 12v wire to the PWM wire of the pump. NO! JUST NO! Bad, very bad idea. You don't feed 12v power to the PWM wire EVER since its ONLY used for PWM signals or for control in general. The diagram you showed is not the same configured header that comes with the pump. Please make sure to research before giving advise as it could risk someone damaging their gear. Again, you don't need anything connected to the PWM header from the pump. The pump will run at a high rate of speed with just the molex power connected to it by default. Once there is power via molex from the PSU, you than turn the PSU on/off when needed too, while priming the pump and filling the loop.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 4/11/2008

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 11:02 PM

(permalink)

GTXJackBauer

ty_ger07

Yes, but he wants to run it at full speed while leak checking a system without powering on that system or needing a second computer to increase the pump speed. Currently, he is plugging it into a second along-side computer header to increase the speed. His question was how to make the pump run full speed without plugging it into a computer's header. The answer, like I gave above, is that, in addition to plugging it into a molex plug, he needs to run a 12 5v wire from a molex plug over into the PWM wire. That is the quickest and easiest way to make it run full speed without needing a fan header or any other type of fan controller

No he doesn't unless he wants to damage his pump. OP, you are NOT going to connect a 12v wire to the PWM wire of the pump. NO! JUST NO! Bad, very bad idea. You don't feed 12v power to the PWM wire EVER since its ONLY used for PWM signals or for control in general.

Actually, it is exactly what he wants to do! I have read the standardization specifications, have taken measurements, have wired up my own custom fan and pump circuitry, have made my own fan controller, and I have quite a lot of general experience on this subject. When you set a PWM fan or pump to 100%, what do you think the voltage and shape of waveform of the "control" "signal" coming out of the PWM header is? At a 100% setting, the normal output to a PWM wire is solid 5v. And that is why I have advised as such. Test for yourself. Connect a voltmeter or oscilloscope (if you have one) up to the PWM wire of any of the fans or pumps in your computer, set their speed to 100%, and tell me the reading you observe. ;) It's a high impedance signal at around 25khz at the potential of 5v with the duty cycle specifying the speed. 0% speed is 0 volts. 25% speed is a square wave which is 25% of the time 5v and 75% of the time 0v. 100% is a solid 5v 100% of the time. I am NOT giving bad advice.

The diagram you showed is not the same configured header that comes with the pump. Please make sure to research before giving advise as it could risk someone damaging their gear.

I know what I am talking about. His gear is the same as any other PWM gear. Only difference is that the power and ground wire goes to a dedicated molex connection (same as the fans and pump in my computer) so that the fan header doesn't get overburdened by excessive load. The wiring is still identical and functions the same way. The diagram I provided is completely accurate except that the "missing" pump power and pump ground wire are connected to a molex connector. Anyone who has one in their hands, sees that there are a total of 4 wires, and sees the purpose of the wires explained in my post above, should understand why they might have a 4-pin PWM header with 4 wires or a 4-pin PWM header with 2 wires alongside a molex connector with 2 wires. The two wires which split off of his pump which go to a 4-pin PWM header are: 1 is the PWM control wire, and 1 is the tachometer feedback wire. The PWM control wire, if connected to 5v, will make the pump run at 100%. He can ignore the tachometer feedback wire and should leave it disconnected since the purpose of that wire is to monitor the actual RPM of the pump using hardware or software which he is not using at this time. Again, you don't need anything connected to the PWM header from the pump. The pump will run at a high rate of speed with just the molex power connected to it by default. Once there is power via molex from the PSU, you than turn the PSU on/off when needed too, while priming the pump and filling the loop.

I am sorry, but this user stated that the pump was not running at 100%. I am not arguing that the pump will run without being connected to a fan header. I am not arguing that it won't be running at a "high rate of speed" versus a "slow rate of speed" since I have no evidence of either in this case; since the default speed when not connected is determined by the manufacturer (as I explained above) and I don't own the exact pump to tell you what the default speed should be. All I can say is that the OP said that the pump wasn't running at 100% until he connects it to a header and sets its speed in software to 100% and was wondering how to force it to run at 100% without needing to connect it to a header. If you want to argue with the OP, feel free.

post edited by ty_ger07 - Saturday, November 04, 2017 11:37 PM

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 4/11/2008

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Controlling a PWM Water Pump

Saturday, November 04, 2017 11:34 PM

(permalink)

Egg on my face. Yikes! PWM wire VMax is 5.25v. I guess I had a lapse in memory. Editing my responses above. Changing +12v to +5v. Otherwise, my response remains as it was. Specifications: http://www.formfactors.org/developer/specs/4_wire_pwm_spec.pdf  For comparison, here is a cheap oscilloscope connected to my pump's PWM wire at 0% speed:  At 50% speed:  At 100% speed:

post edited by ty_ger07 - Sunday, November 05, 2017 0:03 PM

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 4/11/2008

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Controlling a PWM Water Pump

Sunday, November 05, 2017 0:13 PM

(permalink)

I have sent warcobra a PM letting him know that I mistakenly said +12v instead of +5v. If it is too late and he has ruined his pump because of me, I have offered to correct my mistake. I hope that this is this image is clear and that this subject will be safely put to rest. This will ensure that the pump runs at full speed without needing to connect it to a normal 4-pin header and without needing to use any additional hardware or software.  http://img.techpowerup.org/171105/pumpfullspeed.png http://img.techpowerup.org/171105/pumpfullspeed.pngA picture is worth a thousand words.

post edited by ty_ger07 - Sunday, November 05, 2017 0:38 PM

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Sunday, November 05, 2017 0:30 PM

(permalink)

ty_ger07

I have sent warcobra a PM letting him know that I mistakenly said +12v instead of +5v. If it is too late and he has ruined his pump because of me, I have offered to correct my mistake.

No worries. As long as we've cleared out the air is all that matters and I wouldn't worry too much with the OP in hopes he never snuck through and left out the rest of the comments. It happens to the best of us including myself in the past and hope you didn't take any of my comments personally as it was never intended. You made me question myself to the point I had to reread on PWM again. LOL!

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

SethH

Superclocked Member

- Total Posts : 228

- Reward points : 0

- Joined: 3/13/2013

- Status: offline

- Ribbons : 2

Re: Controlling a PWM Water Pump

Friday, November 10, 2017 9:57 PM

(permalink)

Use this: https://www.ekwb.com/shop/ek-cable-pump-testing-adapter(I'm sure other places sell them/make them but I happened to just include this when I ordered my supplies) One end connects to the SATA power cable on your PSU, and the other to the 4 pin connector on the pump. It will run at 100% all the time. I have this pump/res combo: https://www.ekwb.com/shop/ek-xres-140-revo-d5-pwm-incl-sl-pumpIt states: " Operational regime:

- PWM duty cycle: ~ 20-100% - Default behavior: Runs at 100% duty cycle when no PWM feedback signal is present" The adapter above is only 3 pin AKA no PWM signal, meaning it will run at 100% by default.

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 3:35 PM

(permalink)

SethH

Use this: https://www.ekwb.com/shop/ek-cable-pump-testing-adapter

(I'm sure other places sell them/make them but I happened to just include this when I ordered my supplies)

One end connects to the SATA power cable on your PSU, and the other to the 4 pin connector on the pump. It will run at 100% all the time.

I have this pump/res combo: https://www.ekwb.com/shop/ek-xres-140-revo-d5-pwm-incl-sl-pump

It states: "Operational regime:

- PWM duty cycle: ~ 20-100%

- Default behavior: Runs at 100% duty cycle when no PWM feedback signal is present"

The adapter above is only 3 pin AKA no PWM signal, meaning it will run at 100% by default.

That is for a 3-pin voltage controlled pump, not for PWM pumps. It will not work in this case. We're not going to risk ruining the OP's pump when as already stated, he can run the pump with no PWM signal and no point in splicing and dicing wires to make it work either.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

SethH

Superclocked Member

- Total Posts : 228

- Reward points : 0

- Joined: 3/13/2013

- Status: offline

- Ribbons : 2

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 8:02 PM

(permalink)

GTXJackBauer

SethH

Use this: https://www.ekwb.com/shop/ek-cable-pump-testing-adapter

(I'm sure other places sell them/make them but I happened to just include this when I ordered my supplies)

One end connects to the SATA power cable on your PSU, and the other to the 4 pin connector on the pump. It will run at 100% all the time.

I have this pump/res combo: https://www.ekwb.com/shop/ek-xres-140-revo-d5-pwm-incl-sl-pump

It states: "Operational regime:

- PWM duty cycle: ~ 20-100%

- Default behavior: Runs at 100% duty cycle when no PWM feedback signal is present"

The adapter above is only 3 pin AKA no PWM signal, meaning it will run at 100% by default.

That is for a 3-pin voltage controlled pump, not for PWM pumps. It will not work in this case. We're not going to risk ruining the OP's pump when as already stated, he can run the pump with no PWM signal and no point in splicing and dicing wires to make it work either.

Actually, this adapter is perfectly fine and suitable for his needs. FROM the website: " This adapter does not provide any tacho or PWM signal and is recommended to be used only for testing purposes. While connected with this cable, every liquid cooling pump or fan with PWM feature, will run at 100% speed."

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 8:37 PM

(permalink)

You'll have to basically redo the wiring just to turn on the pump when the main PSU or secondary PSU can do the same thing without rewiring and nothing else connected to it. I believe that adapter was initially made for voltage pumps. You can't just connect that 3-pin header to the 4-pin Tach and PWM wires on the pump to power it. You still need the power molex wires involved.

I get what you guys are trying to say but you're only adding more work and making your average joe redo their wiring just to get the pump working with a PSU when I've said there's a much easier way to do it without the risk of wiring the wrong wires together. Not everyone is a electrical engineer out there that deals with custom water cooling and the last thing you need is someone wiring the wrong wires together by accident and frying the pump's board, etc.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

SethH

Superclocked Member

- Total Posts : 228

- Reward points : 0

- Joined: 3/13/2013

- Status: offline

- Ribbons : 2

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 9:34 PM

(permalink)

GTXJackBauer

You'll have to basically redo the wiring just to turn on the pump when the main PSU or secondary PSU can do the same thing without rewiring and nothing else connected to it. I believe that adapter was initially made for voltage pumps. You can't just connect that 3-pin header to the 4-pin Tach and PWM wires on the pump to power it. You still need the power molex wires involved.

I get what you guys are trying to say but you're only adding more work and making your average joe redo their wiring just to get the pump working with a PSU when I've said there's a much easier way to do it without the risk of wiring the wrong wires together. Not everyone is a electrical engineer out there that deals with custom water cooling and the last thing you need is someone wiring the wrong wires together by accident and frying the pump's board, etc.

Oh I agree with that. This shouldn't be more complicated than it needs to be. This is what I did when leak testing my loop using a SECOND PSU (could easily be done with the main one). Second PSU: 1.) Mobo 24-pin shorting connector so the PSU can turn on without being attached to actual motherboard. 2.) Molex connector to PUMP Molex. 3.) The 3-Pin SATA adapter to run the pump at 100% by default. Done.

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 10:01 PM

(permalink)

My apologize. Had no idea you could feed a PWM pump 5v and get full 100% speed. I honestly took all this as you're trying to power the pump via 3-pin period via rewiring from the molex, etc. I just realized you use the molex for power and that adapter to give the PWM 5v to trigger it for full 100% speed. Completely went over my head as I've never heard this in the custom H20 community so my apologize to ty_ger and SethH. I just take this kind stuff very seriously and cautiously and you see, I'm no electrical engineer either. lol Always learning something.

post edited by GTXJackBauer - Saturday, November 11, 2017 10:04 PM

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

SethH

Superclocked Member

- Total Posts : 228

- Reward points : 0

- Joined: 3/13/2013

- Status: offline

- Ribbons : 2

Re: Controlling a PWM Water Pump

Saturday, November 11, 2017 10:17 PM

(permalink)

GTXJackBauer

My apologize. Had no idea you could feed a PWM pump 5v and get full 100% speed. I honestly took all this as you're trying to power the pump via 3-pin period via rewiring from the molex, etc. I just realized you use the molex for power and that adapter to give the PWM 5v to trigger it for full 100% speed. Completely went over my head as I've never heard this in the custom H20 community so my apologize to ty_ger and SethH. I just take this kind stuff very seriously and cautiously and you see, I'm no electrical engineer either. lol

Always learning something.

Oh no no no haha. It's all good. I'd rather have someone be cautious and make SURE something's good before they actually do it than a person who just does whatever the first thing is that they read. I would never re-wire something (for the most part) tbh because in this day and age there's ALWAYS an adapter you can use or a different way to do something that is simple, especially when it comes to computers.

|

quadlatte

CLASSIFIED ULTRA Member

- Total Posts : 5427

- Reward points : 0

- Joined: 9/14/2006

- Location: Greensboro, NC

- Status: offline

- Ribbons : 56

Re: Controlling a PWM Water Pump

Sunday, November 12, 2017 1:13 AM

(permalink)

|

warcobra

Superclocked Member

- Total Posts : 190

- Reward points : 0

- Joined: 5/24/2005

- Status: offline

- Ribbons : 1

Re: Controlling a PWM Water Pump

Sunday, November 12, 2017 2:17 AM

(permalink)

Wow thanks for all the responses guys. I have since got a PWM controller that power's off of the PSU I use for testing. It's a self sustaining system so I have a screen to visually see RPM and can now also test for head pressure and flow on screen as well. Thanks for all of your help. Got to love EVGA fourms. Thanks for all the help.

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Sunday, November 12, 2017 3:00 AM

(permalink)

warcobra

Wow thanks for all the responses guys. I have since got a PWM controller that power's off of the PSU I use for testing. It's a self sustaining system so I have a screen to visually see RPM and can now also test for head pressure and flow on screen as well. Thanks for all of your help. Got to love EVGA fourms. Thanks for all the help.

Curious on what PWM controller you're using? Aquaero?

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|

complexfilter

New Member

- Total Posts : 6

- Reward points : 0

- Joined: 11/18/2018

- Status: offline

- Ribbons : 0

Re: Controlling a PWM Water Pump

Sunday, November 18, 2018 4:48 AM

(permalink)

I am currently using the same pump, EK D5 REVO XRES140, as we are discussing. I connect the power to Molex 4 pin and connect the PWM to the motherboard. I do recognize that when connecting the PWM to the motherboard, the vibration of the pump is tiny while unplugging from the motherboard the vibration is more significant. I do not want to persistently unplug the PWM from the motherboard in order to save the life of the pump; meanwhile, I still want to have a sense of how fast the pump runs, like the percentage of the PWM wave. Does anyone know how to measure the RPM of the EKWB pump connected to EVGA X299 Dark Motherboard? I am currently using Ubuntu 18.04.

|

GGTV-Jon

FTW Member

- Total Posts : 1813

- Reward points : 0

- Joined: 11/25/2017

- Location: WA, USA

- Status: offline

- Ribbons : 19

Re: Controlling a PWM Water Pump

Wednesday, November 21, 2018 5:45 PM

(permalink)

complexfilter

I am currently using the same pump, EK D5 REVO XRES140, as we are discussing. I connect the power to Molex 4 pin and connect the PWM to the motherboard. I do recognize that when connecting the PWM to the motherboard, the vibration of the pump is tiny while unplugging from the motherboard the vibration is more significant. I do not want to persistently unplug the PWM from the motherboard in order to save the life of the pump; meanwhile, I still want to have a sense of how fast the pump runs, like the percentage of the PWM wave. Does anyone know how to measure the RPM of the EKWB pump connected to EVGA X299 Dark Motherboard? I am currently using Ubuntu 18.04.

I have that pump / motherboard combo. Personally I run the pump at 100% all the time. I plugged it into the lower chassis fan header and set it at max in the bios. The 2 CPU fan headers are hooked to the radiator fans and front chassis fans with fan curves setup in the bios I don't see "not" running the pump at 100% doing you any favors. A replacement pump is not that expensive. If you insist on having the speeds less then max then use one of the CPU fan headers and set the stepped speeds / temps

Attached Image(s)

|

GTXJackBauer

Omnipotent Enthusiast

- Total Posts : 10335

- Reward points : 0

- Joined: 4/20/2010

- Location: (EVGA Discount) Associate Code : LMD3DNZM9LGK8GJ

- Status: offline

- Ribbons : 48

Re: Controlling a PWM Water Pump

Thursday, November 22, 2018 4:11 AM

(permalink)

GGTV-Jon

If you insist on having the speeds less then max then use one of the CPU fan headers and set the stepped speeds / temps

The problem with going based on component temps is whether it's a fan or pump, it will behave very erratic and become unpleasantly noisy and don't think constant ramp up and down will be any good for the longevity of the motors. Best way to remedy this is with either delta temps or water temps for example since it will slowly heat up and cool off. If that isn't an option, setting and forgetting to fixed speeds is fine for fans and pumps up to the users liking based on performance and audibles. They just need to play with it to find the common ground.

Use this Associate Code at your checkouts or follow these instructions for Up to 10% OFF on all your EVGA purchases: LMD3DNZM9LGK8GJ

|