Cordell_Wanless

New Member

- Total Posts : 5

- Reward points : 0

- Joined: 2021/08/10 13:32:38

- Status: offline

- Ribbons : 0

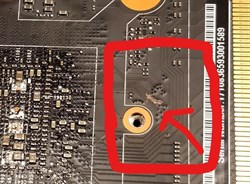

Hello, Recently, I decided to repaste my 1080Ti as it has been in use for 4 years and I wanted to try reducing temperatures. I was doing this while extremely tired at 2 AM and things went smoothly until one of the final screws in the reassembly process. I wasn't paying attention and was pushing my screwdriver on the traces that filled the gaps of the backplate rather than screwing in the screws. As such, I completely disconnected 3 of the copper traces coming off of the GPU (see pics below, sorry for low quality, limited by upload size requirements). Now, the GPU will power up but the fan directly over the GPU spins at 100% and there is no display output, nor a recognition on the monitor of it even being attached. What's more, the system will not post, and, on one system with indicator lights, the CPU light has come on (although at another time the VGA light was instead on). This has been tried in two different systems with entirely different hardware and monitors with the same results. Now, my aim is to repair this card if whatsoever possible, as I don't really want to buy another card with the frequency that I can play and current GPU prices. Since EVGA unfortunately does not do product repairs outside of warranty, and I do not have any friends in my University's electrical engineering department, I plan to use a conductive ink pen to connect the traces by putting on a few layers and then utilizing an exacto knife with a mounted phone as a microscope to make individual connections. I assume that if the traces touch each other, something could go very wrong, which is the purpose of the exacto knife. I have also used the blunt side of the knife to peel back the non-conductive covering so that it is easier to connect the traces. Is my current plan whatsoever achievable so long as in testing prior to application the ultra-thin pen drawn "traces" have low resistance and can be disconnected with the exacto? Does anyone have a better idea on how to do this or who to contact? Is it hopeless and since I have tried to boot the card several times since severing the traces it is now more than likely bricked? Thank you for all your help!

Attached Image(s)

|

HeavyHemi

Omnipotent Enthusiast

- Total Posts : 13887

- Reward points : 0

- Joined: 2008/11/28 20:31:42

- Location: Western Washington

- Status: offline

- Ribbons : 135

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/10 14:37:23

(permalink)

☄ Helpfulby Cordell_Wanless 2021/08/10 16:01:04

Cordell_Wanless

Hello,

Recently, I decided to repaste my 1080Ti as it has been in use for 4 years and I wanted to try reducing temperatures. I was doing this while extremely tired at 2 AM and things went smoothly until one of the final screws in the reassembly process. I wasn't paying attention and was pushing my screwdriver on the traces that filled the gaps of the backplate rather than screwing in the screws. As such, I completely disconnected 3 of the copper traces coming off of the GPU (see pics below, sorry for low quality, limited by upload size requirements). Now, the GPU will power up but the fan directly over the GPU spins at 100% and there is no display output, nor a recognition on the monitor of it even being attached. What's more, the system will not post, and, on one system with indicator lights, the CPU light has come on (although at another time the VGA light was instead on). This has been tried in two different systems with entirely different hardware and monitors with the same results.

Now, my aim is to repair this card if whatsoever possible, as I don't really want to buy another card with the frequency that I can play and current GPU prices. Since EVGA unfortunately does not do product repairs outside of warranty, and I do not have any friends in my University's electrical engineering department, I plan to use a conductive ink pen to connect the traces by putting on a few layers and then utilizing an exacto knife with a mounted phone as a microscope to make individual connections. I assume that if the traces touch each other, something could go very wrong, which is the purpose of the exacto knife. I have also used the blunt side of the knife to peel back the non-conductive covering so that it is easier to connect the traces. Is my current plan whatsoever achievable so long as in testing prior to application the ultra-thin pen drawn "traces" have low resistance and can be disconnected with the exacto? Does anyone have a better idea on how to do this or who to contact? Is it hopeless and since I have tried to boot the card several times since severing the traces it is now more than likely bricked?

Thank you for all your help!

First step is to clean up all debris so you're left with only solidly connected material. With the exacto knife, you should be able to define each traces original path. As much as possible restore the traces to their original shape and path. If you have to remove a bit of copper, that is fine. What you want is restore the path as much as possible, much like repairing a dent. With the short distance, with a bit of dexterity, you should be able to bridge the gap using solder vice a conductive pen. Mistake one was booting the GPU after causing the damage.  I don't know if repairing this will restore the GPU. I'd say the odds are good if nothing else smoke checked. I could do it with one of these https://www.amazon.com/GLE2016-Soldering-Adjustable-Temperature-Different/dp/B01N413T8U/ref=asc_df_B01N413T8U/?tag=hyprod-20&linkCode=df0&hvadid=241994862626&hvpos=&hvnetw=g&hvrand=17659723572839110832&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9033520&hvtargid=pla-523741599723&psc=1

EVGA X99 FTWK / i7 6850K @ 4.5ghz / RTX 3080Ti FTW Ultra / 32GB Corsair LPX 3600mhz / Samsung 850Pro 256GB / Be Quiet BN516 Straight Power 12-1000w 80 Plus Platinum / Window 10 Pro

|

Cordell_Wanless

New Member

- Total Posts : 5

- Reward points : 0

- Joined: 2021/08/10 13:32:38

- Status: offline

- Ribbons : 0

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/10 16:00:39

(permalink)

Heavy,

Thanks for the advice. I realized I did it but didn't pull the backplate back off so I decided to just plug it in and hope it worked...big mistake. With regard to soldering, that was my first idea, particularly since I live with someone who is somewhat experienced in doing that. Unfortunately, we are unsure if his solder (which is similar to the one you linked) would work in this use case. The picture I provided is somewhat deceiving, as I could only upload one and went somewhere between zoomed out and zoomed in. The entirety of the destroyed area is maybe 1-1.5 mm wide, and in that area there are 3 individual copper traces. Because this is so tight, we thought that all the traces would end up connecting to one another. Would a 1mm solder like the one you linked come out thinner than that, or would I just have to use the exacto knife to separate them into individual traces after soldering? I am guessing that if they are all connected together they will not work.

Thanks again!

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 2008/04/10 23:48:15

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/10 18:24:50

(permalink)

☄ Helpfulby Cordell_Wanless 2021/08/11 14:19:34

You need to lay a small piece of wire down to bridge the gap. You can't just lay down a 1mm piece of solder and cut them apart. Considering your question, I am concerned that the chances are very slim that you will be able to repair the card without hopelessly making it worse instead. You don't appear to have any experience. You should find someone with experience who can repair it for you or with you. At a bare minimum, you need magnification, small wire to bridge the gap, tweezers, solder, flux, and a soldering iron which won't get too hot and melt the existing traces off of the circuit board. If you use enough flux, you don't need to worry about the different traces connecting as one big blob. You should never need to physically cut solder. Flux is marvelous stuff. Fat solder can be used on thin traces and thin solder on fat traces. The size of the trace isn't directly proportional to the size of the solder. You don't lay the solder down as you are envisioning. Solder flows via surface tension. It needs something to flow onto.

post edited by ty_ger07 - 2021/08/11 09:43:49

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

Cordell_Wanless

New Member

- Total Posts : 5

- Reward points : 0

- Joined: 2021/08/10 13:32:38

- Status: offline

- Ribbons : 0

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/11 14:15:52

(permalink)

ty,

Thank you for the suggestions. This video is actually one of the first things I found when my roommate suggested that he just solder it. The issue is less making the solder itself the size of the trace, and moreso getting enough solders down. I measured it, and I have 7 traces within about 2 mm of each other, with the 3 broken ones being within 1 mm of each other in total diameter. Each trace appears to be maybe .25 mm wide (so .75 mm total of copper), with the remaining .25 mm out of the 1mm being the separations between each. Is it even possible to complete this job without a very expensive nano-solder or an actual dedicated machine? That is what I am concerned about. One trace in the video is the width of essentially the entire area that I need to repair, which is 3 traces. Basically, I'm just not sure if this is doable by anything but a machine with the amount of precision required. While my exacto knife is fine enough to just barely trace between the lines while using my phone as a magnifying glass, I'm not sure how exactly anyone would solder that. Thanks once again!

|

Cordell_Wanless

New Member

- Total Posts : 5

- Reward points : 0

- Joined: 2021/08/10 13:32:38

- Status: offline

- Ribbons : 0

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/11 14:19:30

(permalink)

Alternatively, did you realize that was the situation and I am just exposing my lack of knowledge on flux? would enough flux theoretically make it possible to complete this, even if my solders end up being like .7 mm wires that basically just end up converging onto one another? Could I theoretically peel back the covering at separate spots so that I could just run the solder over non-conductive material and thereby have each one separated by a good bit of space to ensure no crossover?

I apologize for any stupid questions and my lack of experience. I have some friends that I think would be capable of this (welders/electricians) but I just want to pick your brain on the best possible method. Thanks once again.

|

Cordell_Wanless

New Member

- Total Posts : 5

- Reward points : 0

- Joined: 2021/08/10 13:32:38

- Status: offline

- Ribbons : 0

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/11 14:30:22

(permalink)

One more dumb idea - I just got a conductive silver ink pen that has a high melting point (well above my thermal limits) and resistance of about .005 over 2.5 cm. Could I do the idea of soldering over the nonconductive material but instead just use the pen? That way I could peel off areas with the exacto and make sure that everything is quite seperated. Sorry once again, and I greatly appreciate anyone taking the time to help a complete noob out.

|

ty_ger07

Insert Custom Title Here

- Total Posts : 16602

- Reward points : 0

- Joined: 2008/04/10 23:48:15

- Location: traveler

- Status: offline

- Ribbons : 271

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/11 14:43:13

(permalink)

Flux will make it so that the solder flows very thin and bonds well. Essentially, the thickness of the solder can be reduced to hardly nothing. If you accidentally add too much solder, you just wick it off.

That being the case, if you can physically fit the wires without them touching, then you can solder them without them touching. It is a matter of difficulty and practice. On the other hand, if you can't lay the wires down without them touching, then you obviously need smaller wires, or need to lay them down in a different pattern.

I have never used conductive ink, and I don't particularly trust it to provide a good connection for an indefinite period of time.

ASRock Z77 • Intel Core i7 3770K • EVGA GTX 1080 • Samsung 850 Pro • Seasonic PRIME 600W Titanium

|

HeavyHemi

Omnipotent Enthusiast

- Total Posts : 13887

- Reward points : 0

- Joined: 2008/11/28 20:31:42

- Location: Western Washington

- Status: offline

- Ribbons : 135

Re: Repairing Damaged 1080Ti SC2 Traces

2021/08/11 16:58:55

(permalink)

Cordell_Wanless

One more dumb idea - I just got a conductive silver ink pen that has a high melting point (well above my thermal limits) and resistance of about .005 over 2.5 cm. Could I do the idea of soldering over the nonconductive material but instead just use the pen? That way I could peel off areas with the exacto and make sure that everything is quite seperated. Sorry once again, and I greatly appreciate anyone taking the time to help a complete noob out.

I see the vid was posted. What I have done is use a single strand from a 18 gauge PCIe cable cut the same length as the gap. I lay that down in the channel made by cleaning out and repairing the original trace path. It's relatively easy to solder and tin the length between the two points. A bit of flux paste will hold the wire in place. All it takes is dexterity and attention to detail. Pro tip: nothing is stopping you from practicing on a junk PCB board.

post edited by HeavyHemi - 2021/08/11 17:00:53

EVGA X99 FTWK / i7 6850K @ 4.5ghz / RTX 3080Ti FTW Ultra / 32GB Corsair LPX 3600mhz / Samsung 850Pro 256GB / Be Quiet BN516 Straight Power 12-1000w 80 Plus Platinum / Window 10 Pro

|