How to build a CNC MACHINE

I recently did a complete rebuild of my CNC machine, so I figure I could at least show the original build.

First, to make your life easy and if you don't know jack about making a milling machine from scratch, do the next best thing and buy a milling machine. There are so many different kinds to suit your budget or work.

I hate to say this, but you need to put your budget aside and think of what you want to make with your machine. If your more budget oriented, then you may just have to skip this hobby altogether. You will realize that you didn't spend enough the first time, and end up spending twice as much once you end up buying the proper machine. Remember this, you will see this unfold before you shortly...

While my milling endeavors started quite humble with a sliding cross vise and a drill press I will skip to the next evolution and present the purchased mill:

Harbor Freight Mini Mill (Seig X2)

$599.99 Don't ever pay that price, find 20% coupons online, or wait for sales etc...

One company makes these, but many companies sell them. Its an ideal machine to learn on and as far as milling machine goes, it is THE starter mill. It has a 9" x 4" table travel & it is made in China, so its "good enough" to start with.

Fast forward a few months and I quickly realized that the 4" Y axis (towards you, and away from you) was not going to be enough for me. After doing some research I decided to upgrade. Now remember what I said about spending twice as much to buy the proper tool? Normally I would have had to do that, but now the expression goes: time is money. I had time, not money. SO, I bought a much larger cross sliding table and decided to adapt it to fit that mill. Nothing impossible, but a monumental task for a novice such as myself.

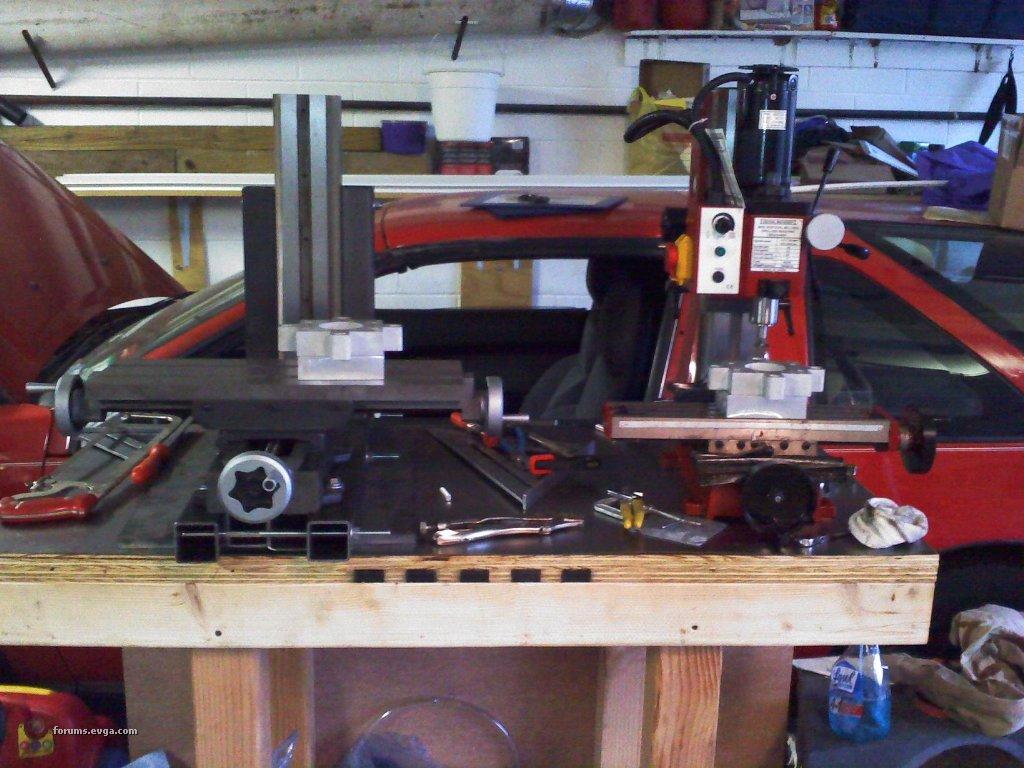

First thing I needed was a table to keep it on:

Not exactly the most sturdy thing, but if u anchor it to a wall its much more sturdy. A fundamental of milling is a sturdy base. You want a rigid machine. This table was not rigid enough, in hind-site, but it has been fixed since then.

Next comes the frame that the vise will be sitting on:

Made from 2x2 square tubular cold-rolled steel.

Just a side by side, you can see how much larger the new table is compared to the factory:

So far we haven't used any fancy tools other then a drill press.

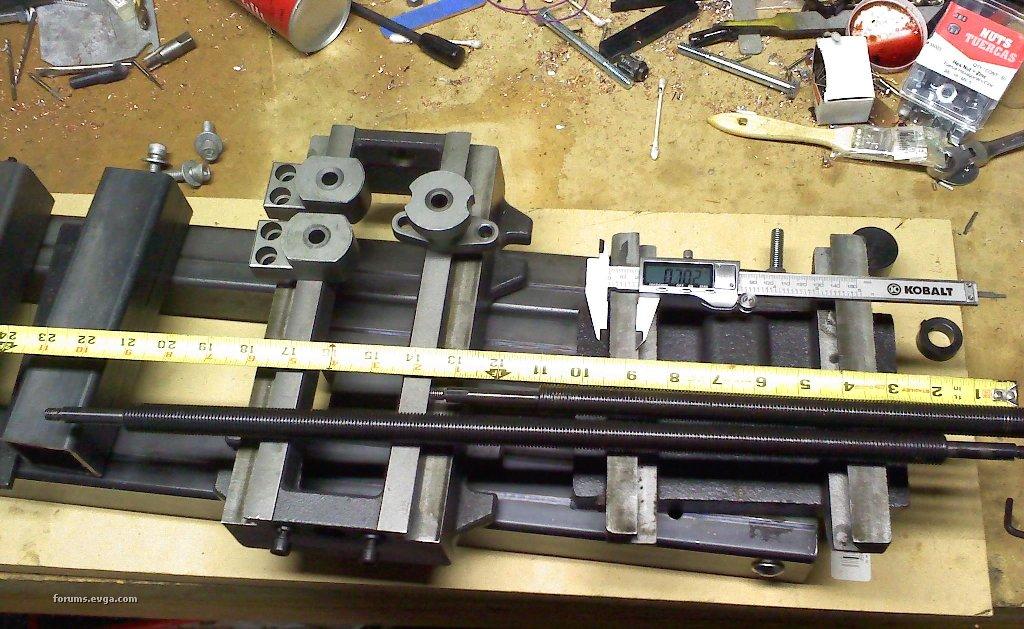

Now comes the breakdown of the new table:

This is every component the table is made of.

One important aspect (probably THE most important) is accuracy. Anyone who has used a table vise at least once in their life has experienced a phenomenon called backlash. This is where your spinning the handle, and the vise doesn't move because of the slop in the screw. Most traditional type of screws have this slop, so CNC machines tend to not have these type of screws in them.

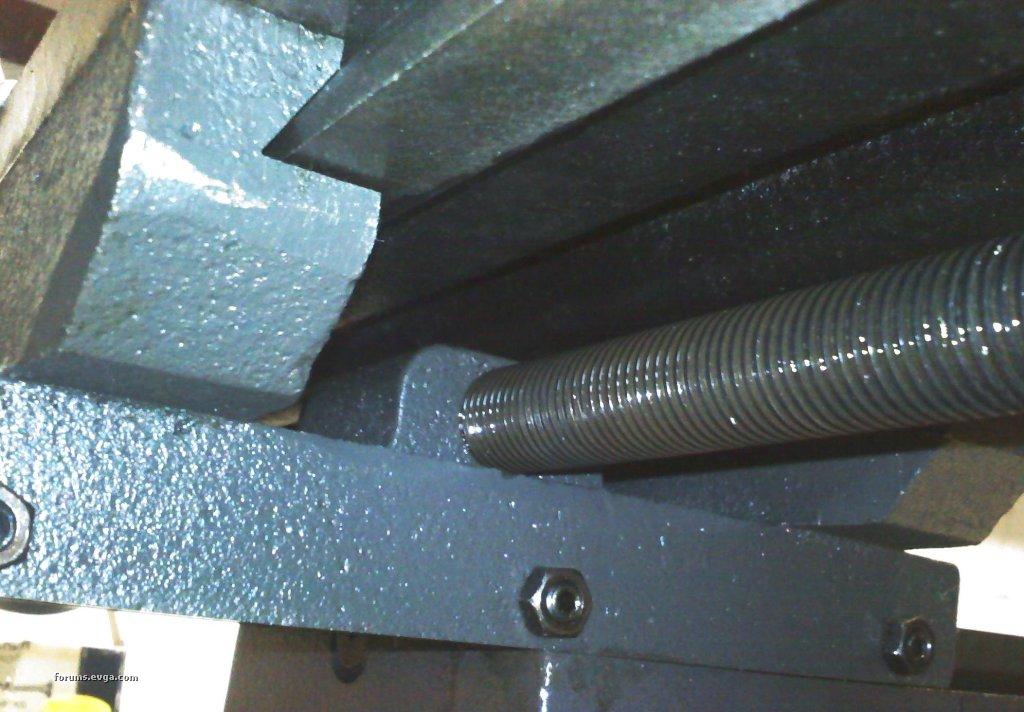

Enter Ballscrews:

They are far more efficient at transferring rotary motion, to linear motion.

This was the tricky part, yanking out the regular screws, and replacing them with ballscrews. Actually the hard part is mounting the ball nut someplace where it doesn't move. Essentially you are replacing this:

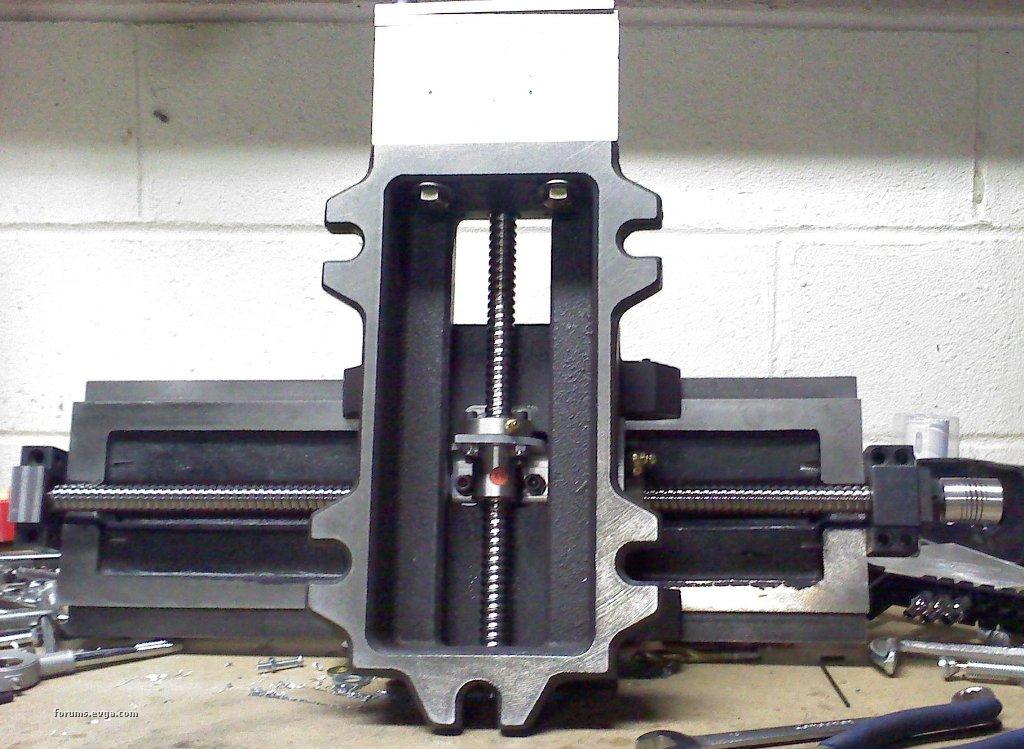

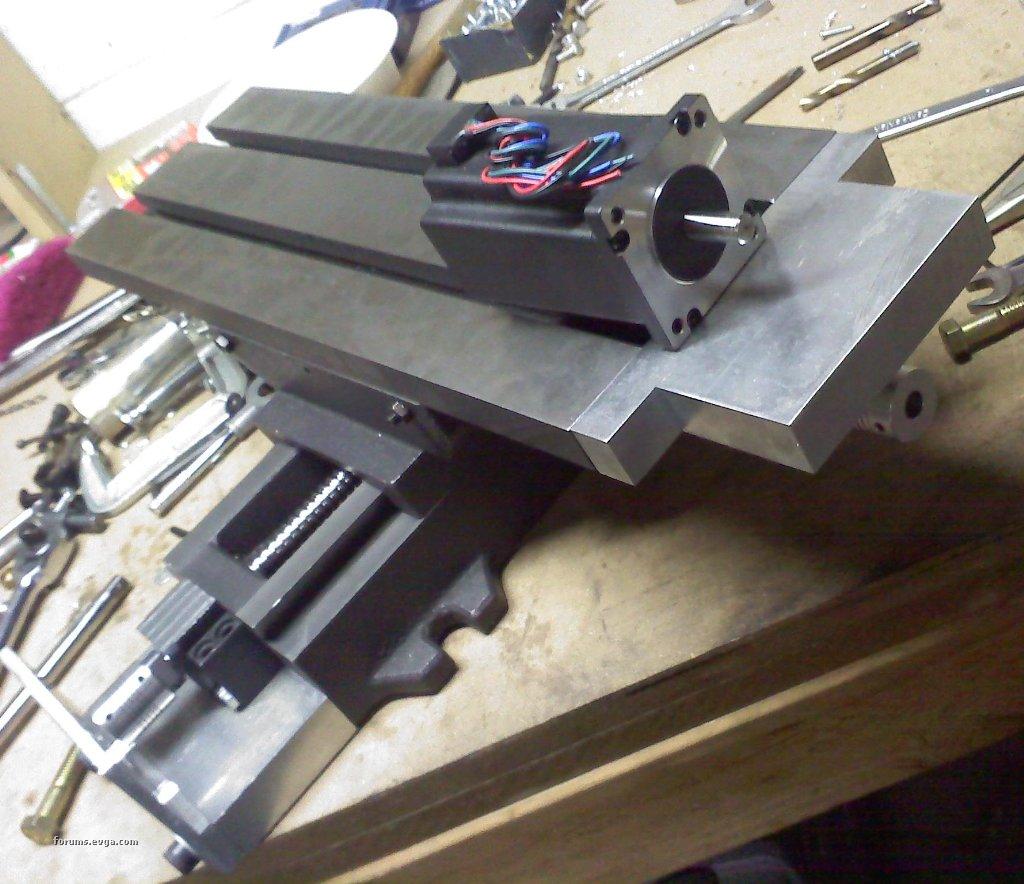

The place to mount the ballnut, and you are replacing the handle, with a motor:

Here is the conversion:

Here is the final product of the original build:

There is so much more involved, but its not outside the realm of possibility. I didn't cover the Z axis (up and down) in this thread simply because I am limited to 10 attachments. I will go into more detail on that when I make a new thread on the current rebuild of this machine since I did a complete rebuild of that.

I hope this helps anyone who was thinking about taking their DIY skills to another level.

post edited by nateman_doo - 2011/12/28 17:10:49