nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Wow, talk about a disappointment. Who let this thing out of the door, let alone okayed it for production? Did the factory run out of 3mm copper and decide to just stamp it out of 1mm foil? The stock heat sink has 3mm copper covering ALL of the memory modules with countless heat pipes behind it. This rink-a-dink plate is a joke, one I don't appreciate paying for nor wasting hours to perform the work on both the card and the computer. You guys completely botched up what could have been a halfway decent product. No doubt we now know what the holdup was for the hybrid cards. There's really no point in even mentioning the TINY contact patch between the 1mm foil and the block. Did someone not tell whoever "designed" this that it needed to handle 85+ watts of heat? A WATER COOLED CARD WITH RAM HOT ENOUGH TO BOIL WATER!?!?! To say I'm extremely disappointed is putting it lightly. This needs a proper solution made immediately. I don't care if you have to go to a local machine shop and have them laser cut out of 2mm flat copper (it'd work, I measured). In-fact, the design would have worked better if it were a 3mm plate covering the entire area just as the factory air cooler has, and the full contact area of the water block contacting the plate. Oh, and the bios? What a joke, anything below 90% power limit drops GPU clock from ~1700mhz at 90% PL to 400mhz at 70% PL. I took my chances installing a random bios I downloaded from a website over deal with that sorry piece of code another 2 minutes. At least I get to adjust the power level while the ram boils water. So tiny, it's almost cute  The stock cooler guys knew what they were doing  Just wow  Water foil fail

|

arestavo

CLASSIFIED ULTRA Member

- Total Posts : 6806

- Reward points : 0

- Joined: 2008/02/06 06:58:57

- Location: Through the Scary Door

- Status: online

- Ribbons : 77

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/02/28 21:12:36

(permalink)

So, out of curiosity have you tried these two things:

1. Set a fan curve for the shroud fan that cools the VRMs and VRAM.

2. (assuming a 3090) Have some air blowing over the backplate to cool the VRAM on the back side?

My VRAM never hits 80C while gaming by doing these things for my 3090 FTW3 with the hybrid cooler, even pulling 500W.

|

Dabadger84

CLASSIFIED Member

- Total Posts : 3426

- Reward points : 0

- Joined: 2018/05/11 23:49:52

- Location: de_Overpass, USA

- Status: offline

- Ribbons : 10

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/02/28 21:34:34

(permalink)

Pretty sure that power draw number is not actually how much heat the memory is outputting. Buildzoid did a video based on Micron's numbers (the GDDR6x on most 3090s is Micron) and it's around 55-70W of heat depending on clocks, OC, and other factors, for all of the chips, combined... meaning spread out over 24 chips (that are, granted, stacked on top of either side of the PCB in all areas).

The 3080 has half the RAM, but the power load/heat production isn't linear from what he said in the video, a 3080 would have less than the 3090 though, obviously.

You can literally stick a 20 x 20 x 10mm aluminum heatsink directly to the memory chips with a thermal pad & their temps drop quite dramatically (I did that on the backplate-side just to see how it would do temps wise - even without applied pressure to maximum contact/squish on the pad, it still lowered Mem2 by 5C over the other mods I'd done... and my Mem2 was already down to 55C before said drop).

It sounds like there's either bad contact or the thermal pads that come on it aren't that great, because even the ol' 3090 FTW3 Hybrid I had before my Kingpin didn't have memory temps anywhere near 75+C (which is about where you'd have to be to get a 90-100C junction temp).

And lastly, reinforcing that post, fan speed matters on the on board fan. Recommend 70-80% if you can handle the "noise" it puts out, that will help, despite the memory mostly being cooled by the AIO, more airflow means lower VRM etc temps which means less PCB heatsoak & thereby lower VRAM temps.

ModRigs: https://www.modsrigs.com/detail.aspx?BuildID=42891 Specs:5950x @ 4.7GHz 1.3V - Asus Crosshair VIII Hero - eVGA 1200W P2 - 4x8GB G.Skill Trident Z Royal Silver @ 3800 CL14Gigabyte RTX 4090 Gaming OC w/ Core: 2850MHz @ 1000mV, Mem: +1500MHz - Samsung Odyssey G9 49" Super-Ultrawide 240Hz Monitor

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/02/28 21:35:40

(permalink)

arestavo

So, out of curiosity have you tried these two things:

1. Set a fan curve for the shroud fan that cools the VRMs and VRAM.

2. (assuming a 3090) Have some air blowing over the backplate to cool the VRAM on the back side?

My VRAM never hits 80C while gaming by doing these things for my 3090 FTW3 with the hybrid cooler, even pulling 500W.

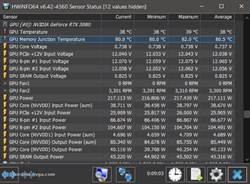

Even better, it's a 3080 ultra and I even added thermal pads behind the ram to the back plate. Here's indisputable proof that absolutely no thought what so ever was put into ram cooling efficacy. This "solution" that they put into this no-validation-was-put-into-the-kit design. With the air cooler running this EXACT same load I was at 82c. 8 minutes with max fans and it didn't budge, at all

Attached Image(s)

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/02/28 21:37:54

(permalink)

|

kevinc313

CLASSIFIED ULTRA Member

- Total Posts : 5004

- Reward points : 0

- Joined: 2019/02/28 09:27:55

- Status: offline

- Ribbons : 22

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/01 11:20:43

(permalink)

Have you considered that you may have installed it wrong or have a crappy setup in general? My factory installed 3080 FTW3 Hybrid runs at about 55C chip, 80C memory junction, at 400-420w board power, normal 4K VRR gaming load. At 1.081-1.1V and 2,085-2,115mhz, typically. The memory plate is very similar to the one used on the 2080 Ti hybrid.

post edited by kevinc313 - 2021/03/02 09:07:06

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/01 14:25:52

(permalink)

kevinc313

Have you considered that you may have installed it wrong or have a crappy setup in general? My factory installed 3080 FTW3 Hybrid runs at about 55C chip, 80C memory junction, at 400-420w board power, normal 4K VRR gaming load. At 1.018-1.1V and 2,085-2,115mhz, typically.

The memory plate is very similar to the one used on the 2080 Ti hybrid.

It's just a poor design, I'll post the results of my modifications later today or tomorrow. The factory HS is 3mm copper utilizing the exact same thermal pads --- It however makes full contact with the thermal pads that make full contact w/ the ram chip. This hybrid plate DOES NOT fully cover the ram, nor are the factory thermal pads large enough. I will be increasing its thermal mass and the resultant mass's ability to conduct heat into the cold plate. The proper way to have designed this would have been to substitute the small round cold plate for a 3mm plate (better still a 5mm plate with recessed CPU die patch -- this can also be punched with a proper press). The CPU would be a few C warmer simply because the ram's heat would be able to carried away by the coolant due to superior contact. Additionally, utilizing nearly 2mm worth of compressed thermal pad to cool the ram is inadequate here. The tolerances created by the spring clip bracket for the factory HS are such that thermal paste could have been utilized on the ram. The spring clip healthily deforms the board that it should have been retained for the hybrid kit that utilizes proper spacing and thermal paste. The overall tolerances of the card are quite impressive -- of course the HS is designed for outliers which I'm betting is quite rare these days. Time to tighten acceptable tolerance limits and minimize if not outright eliminate thermal insulators known as thermal pads.

|

kevinc313

CLASSIFIED ULTRA Member

- Total Posts : 5004

- Reward points : 0

- Joined: 2019/02/28 09:27:55

- Status: offline

- Ribbons : 22

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 06:07:22

(permalink)

nosomo

kevinc313

Have you considered that you may have installed it wrong or have a crappy setup in general? My factory installed 3080 FTW3 Hybrid runs at about 55C chip, 80C memory junction, at 400-420w board power, normal 4K VRR gaming load. At 1.018-1.1V and 2,085-2,115mhz, typically.

The memory plate is very similar to the one used on the 2080 Ti hybrid.

It's just a poor design, I'll post the results of my modifications later today or tomorrow.

The factory HS is 3mm copper utilizing the exact same thermal pads --- It however makes full contact with the thermal pads that make full contact w/ the ram chip. This hybrid plate DOES NOT fully cover the ram, nor are the factory thermal pads large enough. I will be increasing its thermal mass and the resultant mass's ability to conduct heat into the cold plate. The proper way to have designed this would have been to substitute the small round cold plate for a 3mm plate (better still a 5mm plate with recessed CPU die patch -- this can also be punched with a proper press). The CPU would be a few C warmer simply because the ram's heat would be able to carried away by the coolant due to superior contact. Additionally, utilizing nearly 2mm worth of compressed thermal pad to cool the ram is inadequate here. The tolerances created by the spring clip bracket for the factory HS are such that thermal paste could have been utilized on the ram. The spring clip healthily deforms the board that it should have been retained for the hybrid kit that utilizes proper spacing and thermal paste. The overall tolerances of the card are quite impressive -- of course the HS is designed for outliers which I'm betting is quite rare these days. Time to tighten acceptable tolerance limits and minimize if not outright eliminate thermal insulators known as thermal pads.

Please do, I'd be interested to see your results as I would have no problem fabricating a 3mm copper plate myself. Thanks.

|

ZekeSulastin

New Member

- Total Posts : 58

- Reward points : 0

- Joined: 2018/06/06 12:58:13

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 07:07:01

(permalink)

Would you be interested in *selling* copper plates if this works? :)

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 11:23:18

(permalink)

I'm going to be retaining the plate -- the one issue for the approach I'm using is that it's going to be made for my card, and made to utilize the factory HS bracket. The memory and die will be making contact at the same time. By using the stock spring bracket, I'm ensuring the bias of pressure is put to the silicon of the GPU (which should work for a MFG'd block the same, it's a smart retention / pressure loading design). The PCB does flex enough that the pressure bias is put into the GPU silicon. The methods I'm using here are the same that I use in upgrading laptop cooling, it's just I have more room to work with. Where the gain comes from is virtually eliminating the amount of thermal insulator (what I refer to thermal pads as) between the item to be cooled and the heat sink. The link below goes into good detail of how a thermal pads thermal resistance is almost linear to its thickness. Being able to minimize the gap between the HS and face to be cooled substantially increases thermal transfer. As much as I'd like to machine a block for this, the time and cost involved wouldn't be worth it. The time would be better spent just making a full water block for the card. There's a lot that goes into recouping such investment that someone like EK is just more efficient at. I use thermal epoxy and various thicknesses of copper to boost cooling in laptops. Increasing both thermal mass and conduction by promoting more efficient heat transfer into the cooling system. I think a big discrepancy between the 3090 and 3080 users is that 3080s use a much higher percentage of their ram for any given load. For example if both cards were to play a game that utilized 8GB of its ram, the 3090 is spreading that among 24 chips vs the 80s 10. For any same-sized load, that means that the work generated places a 3x higher strain (loosely) on the 3080's 10 chips vs the 90's 24. If the 90 users were to utilize their ram at a percent capacity of that of the 80's, we'd see just how bad of a solution this is, and they'd see just how hot their ram can get. Thermal epoxy has a relatively low thermal conductivity -- about 1/5th that of a really good thermal paste. The trick however is the thickness, or lack thereof. With copper making up a majority of the gap span, the thermal transfer capability it taken up to 20x more efficient. I just did the same thing to a 5600 xt lowering its ram temps 23% vs ambient. The 14c drop in temp did yield a 4c higher core temp on an air cooler, but that's due to the fact that more heat is able to enter the cooling solution. I'd love to see a 20% reduction in ram temps here vs ambient and I'd gladly pay 4c on the core for doing so, but given that I'm upgrading fans on the radiator at the same time, I expect a 2c core rise at best. Due to manufacturing variances in boards / component placement, this type of approach which is basically filling the gap with copper is best done on a 1:1 basis with minimal hope of having the same solution glove-fit another GPU. I suspect the tolerances are such that it'd also work on most other cards the cooler fits with, but I don't have to worry about such compatibility as this is specifically for my card. The thing about thermal epoxy though -- there is no undo button. You've got 1 chance to get it right else risk mangling something up trying to undo the bond. The pic below is the finished product on the 5600 xt. htt ps://www.lord.c om/products-and-solutions/electronic-materials/thermal-management-materials/gap-fillers-vs-thermal-pads

post edited by nosomo - 2021/03/02 11:50:14

|

kevinc313

CLASSIFIED ULTRA Member

- Total Posts : 5004

- Reward points : 0

- Joined: 2019/02/28 09:27:55

- Status: offline

- Ribbons : 22

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 11:35:00

(permalink)

nosomo

I use thermal epoxy and various thicknesses of copper to boost cooling in laptops. Increasing both thermal mass and conduction by promoting more efficient heat transfer into the cooling system.

Yeah I think people forget copper is about 100x more thermally conductive than paste or pads.

|

vulcZ

iCX Member

- Total Posts : 301

- Reward points : 0

- Joined: 2005/05/10 14:19:10

- Location: Southern California

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 11:40:47

(permalink)

Just curious, although I think I already know the answer to this, but what are you doing that makes your memory junction temps get that high? There's only one thing I can do on my 3080 or 3090 that can get my memory junction temps anywhere near that high, and it isn't gaming.

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 11:53:05

(permalink)

vulcZ

Just curious, although I think I already know the answer to this, but what are you doing that makes your memory junction temps get that high? There's only one thing I can do on my 3080 or 3090 that can get my memory junction temps anywhere near that high, and it isn't gaming.

My cards are never idle and I enjoy gaming. My reply is simple --- Like I tell the ATF when they ask what's the purpose of requesting a tax stamp to buy a MG -- "all legal purposes" (post above added additional info)

|

skyline090

Superclocked Member

- Total Posts : 155

- Reward points : 0

- Joined: 2018/03/17 16:02:59

- Status: offline

- Ribbons : 1

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 12:00:34

(permalink)

Custom loop w/EK blocks - 12900k, 4090 FE, z690 Apex, G.Skill DDR5 6600 c32, EVGA 1000 P6, Lian Li O11D XL

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 12:09:16

(permalink)

skyline090

I installed the hybrid kit on my 3080ftw3 in January. If it makes you feel better, my junction temp is currently at 96C. I did some reading up on this topic and temps are withing operating spec.

https://www.reddit.com/r/EtherMining/comments/l5s4ja/gpu_memory_junction_temp_how_hot_is_too_hot_rtx/

edit: current mem temps (not gpu junction) are: 59, 54 and 52C. GPU is currently mining since I am at work.

It's not about spec, it's about the PCB and solder. Solder formulations haven't changed -- 100c will see issues around 2-4 years in. Heat is the enemy in electronics. Always has been, always will be. There's no reason for something in the 70w range to be that hot with water cooling. Why someone at EVGA hasn't stood up and said "this is crazy, let's make it right" beats me - maybe they did and they're no longer employed? Thermal resistance is about temp -- it runs hotter and produces more heat, the hotter it gets. Thermal runaway happens specifically for this reason, the hotter something gets, the more resistance it has and the hotter it runs. The GPU core of the 3080 has thermal profiles in it that I've observed so far that start modify its functionality starting at 35c. I've seen another at 55c so I'm guessing their boost algo operates in increments of 5c blocks and accounts for increasing resistance. Given the cores transistor count, I'm sure it makes a much bigger difference on that scale. That's more to illustrate the importance of it though. For a temp sensor to read a given setting, whatever is generating that heat will be hotter than the sensor. There's ways around that with calibration, but such accuracy isn't warranted at this level. The temp sensors here are a "goodnuff" solution.

post edited by nosomo - 2021/03/02 12:17:28

|

vulcZ

iCX Member

- Total Posts : 301

- Reward points : 0

- Joined: 2005/05/10 14:19:10

- Location: Southern California

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 12:15:20

(permalink)

nosomo

vulcZ

Just curious, although I think I already know the answer to this, but what are you doing that makes your memory junction temps get that high? There's only one thing I can do on my 3080 or 3090 that can get my memory junction temps anywhere near that high, and it isn't gaming.

My cards are never idle and I enjoy gaming. My reply is simple --- Like I tell the ATF when they ask what's the purpose of requesting a tax stamp to buy a MG -- "all legal purposes"

(post above added additional info)

So you mine. No big deal, many of us here do. I'm not sure there's a need to be secretive about it. So a couple of things. Your MJTs are within spec, as the poster above mentioned. Also, lowering your MJT by a substantial amount is incredibly hard to do, especially on a card that doesn't offer direct PCB contact to the backplate. I have a 3080 FTW3 that uses the hybrid cooler which I installed myself. I too suspected that this "upgrade" was actually way worse for MJT because of the little cold plate, and because the stock cooler has MUCH better direct memory cooling, as you noted. However my good friend, whom also has a 3080 FTW3 and also mines, did some testing and his MJTs are really no better than my hybrid cooler's, despite significantly more surface area available to the memory ICs on the stock cooler. This was HUGE surprise to me, but also a relief because it meant I wouldn't go back to the stock cooler :) Finally, I think the cooler does a better job than we think. I have done a lot of testing, and MJT responds fairly well to an increase in radiator fan speed. If anything, I think something that would help more is to somehow find a way to attach thermal pads to the back of the card to help the backplate soak up a lot of PCB's heat (especially around the memory area), and then on top of that add additional heatsinks to the top of the backplate. That's actually my next project as soon as I'm done benching my 3090 Kingpin. I am going document all of my finds after modding the backplate, the same way I did the Kingpin. If it's anything like the Kingpin, the improvements will be decent but not game changing. All of the ICX sensors will probably drop a ton, but MJT will still be high. Thankfully though, again, 90-100 is within spec and a temp I am comfortable running them at for now. For the record, on my 3080 FTW3, with my current fan curve, they go from 84-94 depending on ambient temps. In the last 13 hours of HWiNFO monitoring, the MJT averaged 87.7C and never went above 94, and this is before my backplate mod. Lastly, I think it's really unfair to pin this on EVGA. Up until a month ago none of us knew what MJT even was. And these cards are designed/tuned for gaming, not for mining. I think EVGA should be thankful that their fanbase is cognizant of MJT and go through (some silly) lengths to try and cool them, but calling EVGA designers stupid for not considering miners when designing this card is unfair IMO.

|

skyline090

Superclocked Member

- Total Posts : 155

- Reward points : 0

- Joined: 2018/03/17 16:02:59

- Status: offline

- Ribbons : 1

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 12:28:22

(permalink)

nosomo

It's not about spec, it's about the PCB and solder. Solder formulations haven't changed -- 100c will see issues around 2-4 years in. Heat is the enemy in electronics. Always has been, always will be. There's no reason for something in the 70w range to be that hot with water cooling. Why someone at EVGA hasn't stood up and said "this is crazy, let's make it right" beats me - maybe they did and they're no longer employed?

Thermal resistance is about temp -- it runs hotter and produces more heat, the hotter it gets. Thermal runaway happens specifically for this reason, the hotter something gets, the more resistance it has and the hotter it runs. The GPU core of the 3080 has thermal profiles in it that I've observed so far that start modify its functionality starting at 35c. I've seen another at 55c so I'm guessing their boost algo operates in increments of 5c blocks and accounts for increasing resistance. Given the cores transistor count, I'm sure it makes a much bigger difference on that scale. That's more to illustrate the importance of it though.

For a temp sensor to read a given setting, whatever is generating that heat will be hotter than the sensor. There's ways around that with calibration, but such accuracy isn't warranted at this level. The temp sensors here are a "goodnuff" solution.

I get what you're saying, thermally speaking. I do not believe a high degree of fault (if any) falls on EVGA. I believe the difference is if one is satisfied with their card or not. With every new metric there will be something I'm sure. I feel my card performs better than most, so I do not have anything to complain about. I also maintain my equipment, which factors into the lifespan of the product.

Custom loop w/EK blocks - 12900k, 4090 FE, z690 Apex, G.Skill DDR5 6600 c32, EVGA 1000 P6, Lian Li O11D XL

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 12:31:05

(permalink)

vulcZ

...

Oh no, NV specifically said these are for mining and issued the reference PCB design and cooling requirements as such. Go back and watch the kitchen release again if you didn't pick up on it. Micron's spec for the memory hints at trying to keep it at 95c or less. Thermal throttling begins around 110c. Thermal throttling isn't meant to be an electronic governor, it's meant to be a hinderance so you fix the problem, not bounce off the rev limiter. This isn't a laptop, and even in a laptop thermal limits should never be touched but in extreme circumstances. Anyway, onto the fix.

|

Dwarfy

SSC Member

- Total Posts : 704

- Reward points : 0

- Joined: 2010/10/27 12:15:17

- Location: South-West UK

- Status: offline

- Ribbons : 5

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/02 15:46:38

(permalink)

FYI solder has changed, it no longer contains lead.

The soldering irons where I work for lead free solder are set to 450 degrees C, if your card hits half that then you might have other problems ;)

Also half that was the temp for leaded solder which did suffer from dry joints if it had many hot cold cycles.

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/04 20:18:38

(permalink)

Dwarfy

FYI solder has changed, it no longer contains lead.

The soldering irons where I work for lead free solder are set to 450 degrees C, if your card hits half that then you might have other problems ;)

Also half that was the temp for leaded solder which did suffer from dry joints if it had many hot cold cycles.

Correct, and for whatever reason the leaded version seems to be much better at not breaking.

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/04 20:35:21

(permalink)

Dabadger84

Pretty sure that power draw number is not actually how much heat the memory is outputting. Buildzoid did a video based on Micron's numbers (the GDDR6x on most 3090s is Micron) and it's around 55-70W of heat depending on clocks, OC, and other factors, for all of the chips, combined... meaning spread out over 24 chips (that are, granted, stacked on top of either side of the PCB in all areas).

The 3080 has half the RAM, but the power load/heat production isn't linear from what he said in the video, a 3080 would have less than the 3090 though, obviously.

Happened to stumble across BZ's vid the other day -- the 3090 uses ~52w of power across 24 chips, the 3080 uses ~42w across 10 chips. That translates to 4.2w per chip with the 3080 vs 3090's 2.17w -- has nearly double the heat to dissipate per area. These ram chips just love to run quite hot for whatever reason. Still no reason to skimp out on cooling. Cooler mod was a success -- regardless of fan speeds mem bounces between 80 and 82 with an average of 80.5c. Core is showing ~4c warmer -- different paste was used this round as the kryonaut ran dry. Paste used on ram is MX5

post edited by nosomo - 2021/03/04 20:40:41

Attached Image(s)

|

dng25

New Member

- Total Posts : 77

- Reward points : 0

- Joined: 2011/12/23 20:40:58

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/04 21:01:17

(permalink)

Seems like you have horrible air flow in your case

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

|

nosomo

Superclocked Member

- Total Posts : 174

- Reward points : 0

- Joined: 2007/08/26 06:13:05

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/03/04 21:10:26

(permalink)

dng25

Seems like you have horrible air flow in your case

3080 puts double the energy into the memory than the 3090 does -- airflow is fine. The 3070 also in the case is running at 49c.

|

Plane19

New Member

- Total Posts : 1

- Reward points : 0

- Joined: 2021/05/09 09:52:20

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/07/08 14:48:11

(permalink)

Thank you all for having this discourse. I was in the same situation of having put the hybrid on the 3080 xc3, then considering whether to put the stock fan back on and was able to determine which was better for me!

|

03whitegsr

Superclocked Member

- Total Posts : 160

- Reward points : 0

- Joined: 2021/01/10 20:11:36

- Status: offline

- Ribbons : 1

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/07/09 23:18:00

(permalink)

Old thread but I've been tossing around some ideas to deal with (what looks like) the mediocre VRAM cooling in the Hybrid cards. I have a hybrid kit to pull measurements off, so I modeled a few things up. I don't have a card apart though to lay it over and see if there are other things to adjust to improve memory coverage. A few important measurements to start with: Stock plate - 0.78mm thick Stock Plate Extrusions - 0.77mm AIO plate Height - 1.56mm (height from where the VRAM plate sits against to the height of the GPU die surface) Thermal Pads - 2.25mm I'm not sure the height difference from the ring around the GPU die to the die it's self, but I'm guessing it's a precision height and "flush" with the GPU die so that it helps take excess contact load? Either way, the plate needs to be under 1.56mm. With the stock plate extrusions, the effective plate thickness is 1.5mm. Ideally, 1.5mm thick copper would be about perfect, but metric plate isn't that common in the US. Common Copper stock in the US: 0.050" (+/-0.005") [1.27 +/- 0.127mm] 0.062" (+/-0.006") [1.575 +/- 1.52mm] I see three methods to do this from a hobbyist perspective 1. Flat 0.050" copper plate with 2.5mm thermal pads. 2. Flat 0.062" plate, lapped down to 1.5mm with 2.5mm thermal pads. 3. Flat 0.050" copper Plate with Bonded copper pads. Could use 0.050" pads with 1.5mm thermal pads (similar to using 2.5mm pads on the stock plate) or 0.062" pads and then 1mm thermal pads. To bond it, I think I'd solder it. I have access to a heat plate and heat guns, despite the large amount of copper, I think I could get a good joint. FWIW, thermal epoxy is like 0.9W/m-K. Solder is 50+W/m-K. The only thing going for epoxy is you'd put it on as thin as possible. I have to wonder if just using thermal grease would be better though. You might be able to just rely on surface tension to keep the copper in place while assembling the card. After that, the thermal pads should hold it all together. FWIW, stock thermal pads were creating a decent amount of deflection in the plate on my card. Going to 2.0mm pads might not be a bad idea anyway. Stock Plate/Thermal Pads  Flat Plate  Stacked Copper Plate

|

Cazer

New Member

- Total Posts : 24

- Reward points : 0

- Joined: 2016/05/14 08:45:26

- Status: offline

- Ribbons : 0

Flagged as Spam (3)

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/07/09 23:46:52

(permalink)

|

Extremity

New Member

- Total Posts : 7

- Reward points : 0

- Joined: 2015/10/03 04:20:04

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/09/10 01:04:41

(permalink)

My 3090 FTW3 with the hybrid cooler is getting 108-110c junction temps. It's killing me inside. I've opened it up twice to make sure everything is making proper contact and that none of the thermal pads have slid off or something, everything is fine. The performance remains surprisingly good, but seeing that junction at 110c makes me lose my mind. While the junction is at 110c, the main temp remains around 48c while mining. I generally run it at 74% power and 85% fan speed (which I'm now increasing, I just hate running over 90% fan) and maintain 118-126mh on average. Would replacing/upgrading the thermal pads make any sort of difference? I ordered two packs of 3mm, and one each of 2mm and 1mm for another card (MSI -- def needs them) and to have some extra. Can anybody give me any insight as to whether this would help, and which I should go with if so? I've read the entire thread but can't tell if the consensus is that thinner pads would be better to reduce resistance before the copper, or if thicker would be better to ensure they're properly sandwiched.

post edited by Extremity - 2021/09/10 01:06:18

|

richard203

New Member

- Total Posts : 76

- Reward points : 0

- Joined: 2021/05/12 19:38:24

- Status: offline

- Ribbons : 0

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/09/10 02:51:05

(permalink)

my 3090 hybrid kit usually 98-102c i used for mining

|

kevinc313

CLASSIFIED ULTRA Member

- Total Posts : 5004

- Reward points : 0

- Joined: 2019/02/28 09:27:55

- Status: offline

- Ribbons : 22

Re: 3080 3090 Hybrid --- 1mm??? 1mm!?!? What in the heat?

2021/09/10 05:59:05

(permalink)

Extremity

My 3090 FTW3 with the hybrid cooler is getting 108-110c junction temps. It's killing me inside. I've opened it up twice to make sure everything is making proper contact and that none of the thermal pads have slid off or something, everything is fine. The performance remains surprisingly good, but seeing that junction at 110c makes me lose my mind. While the junction is at 110c, the main temp remains around 48c while mining. I generally run it at 74% power and 85% fan speed (which I'm now increasing, I just hate running over 90% fan) and maintain 118-126mh on average.

Would replacing/upgrading the thermal pads make any sort of difference? I ordered two packs of 3mm, and one each of 2mm and 1mm for another card (MSI -- def needs them) and to have some extra. Can anybody give me any insight as to whether this would help, and which I should go with if so? I've read the entire thread but can't tell if the consensus is that thinner pads would be better to reduce resistance before the copper, or if thicker would be better to ensure they're properly sandwiched.

You have a bad mount or swapped the factory pads to some (fake) aftermarket ones from a dodgy vendor. Or you don't have proper/sufficient paste between the AIO and vram plate. Or you probably want to get a better fan config going on the rad.

post edited by kevinc313 - 2021/09/10 06:00:16

|